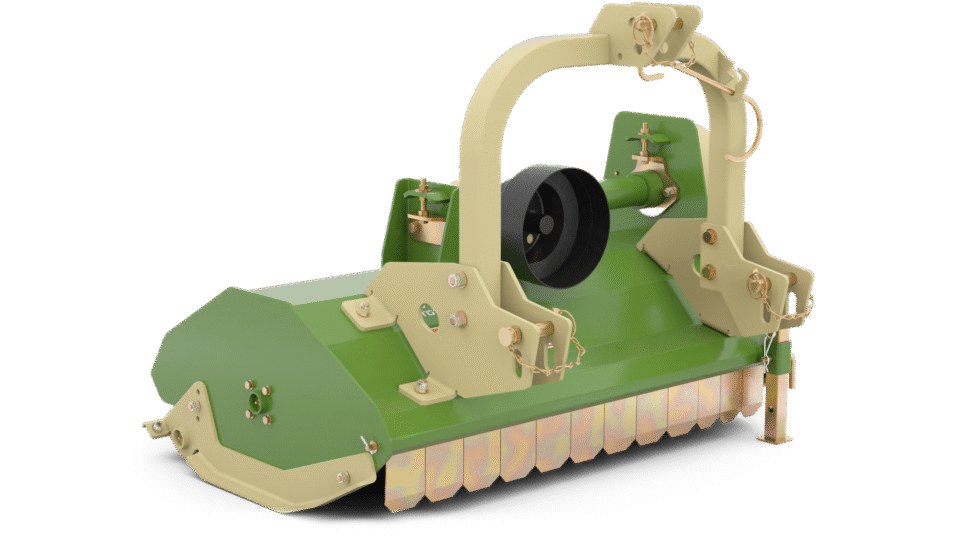

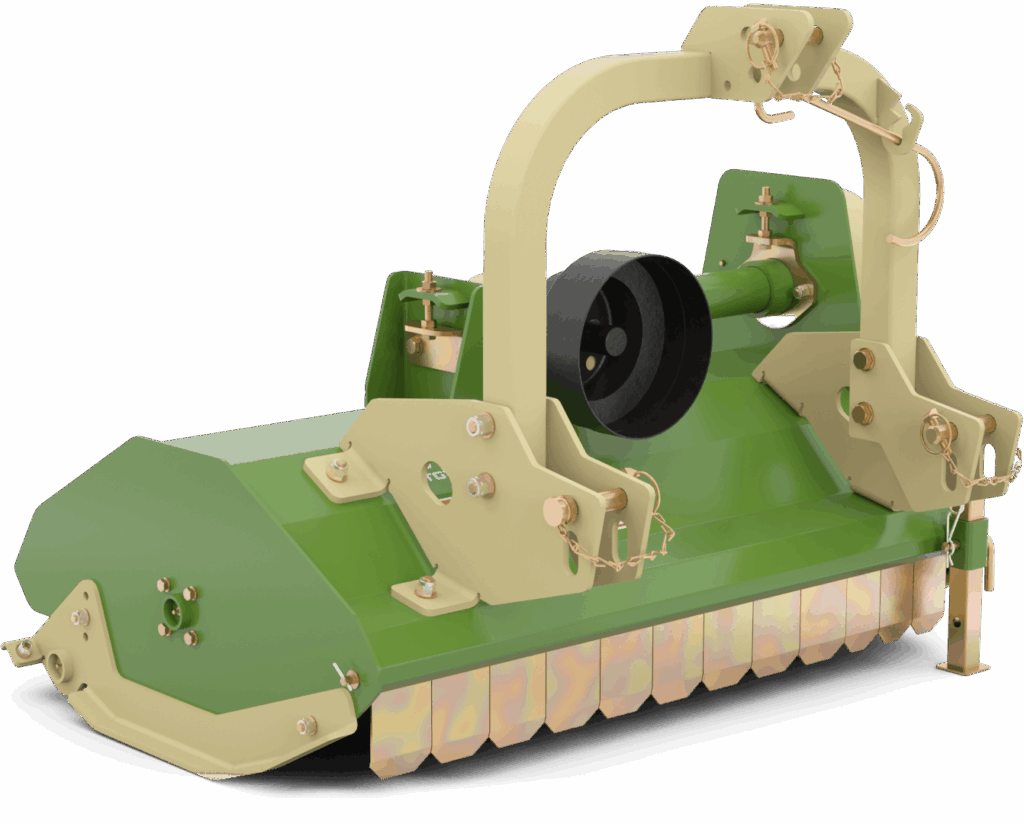

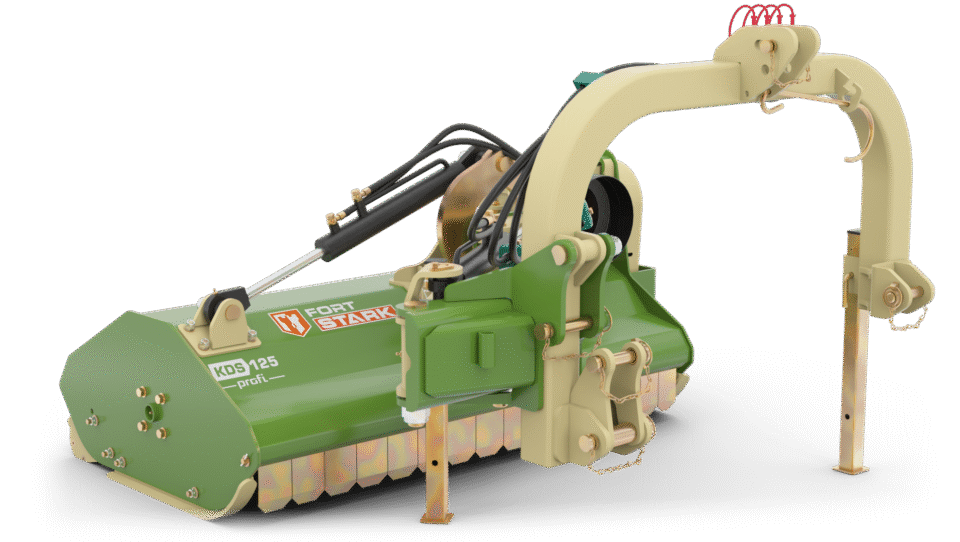

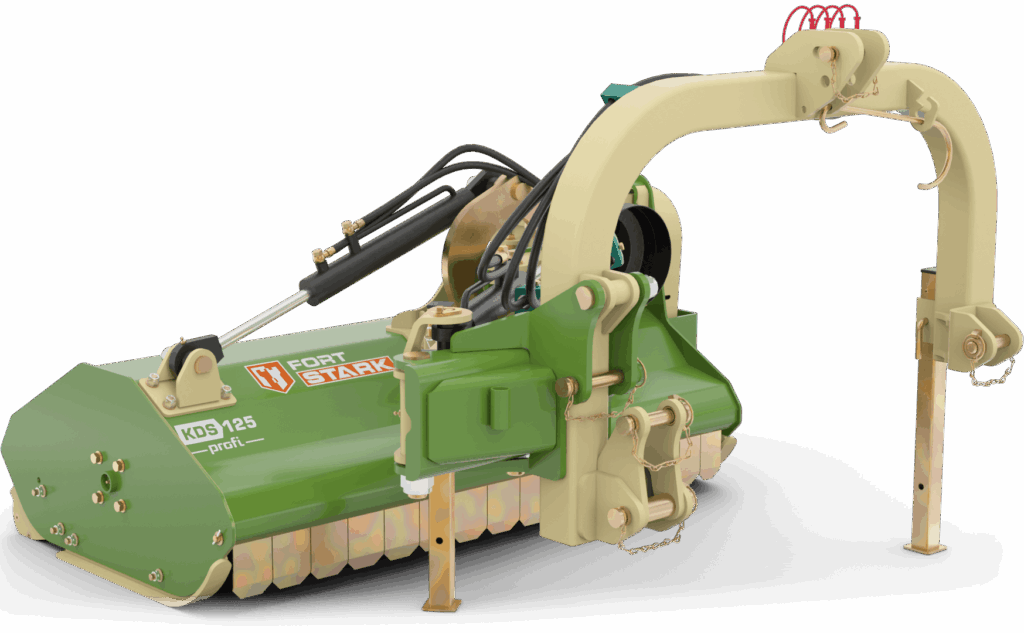

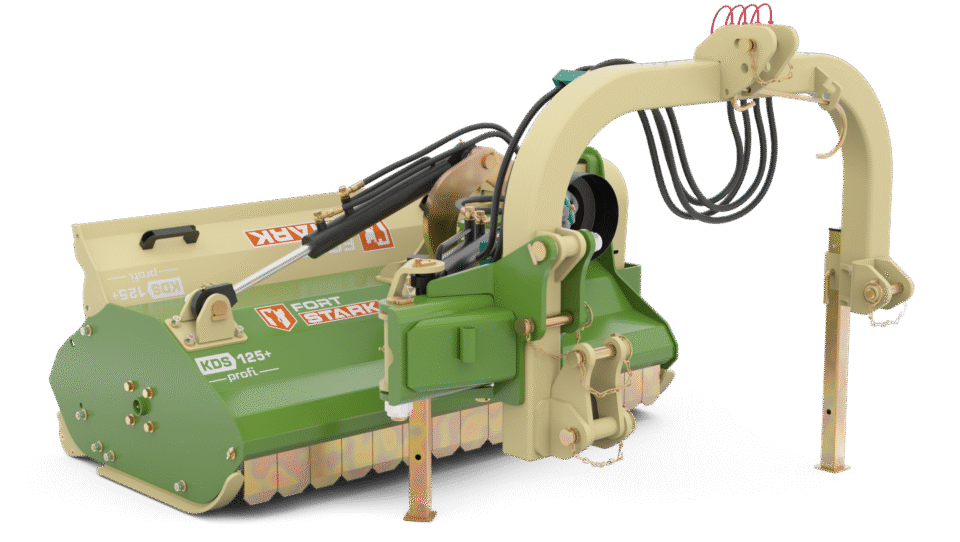

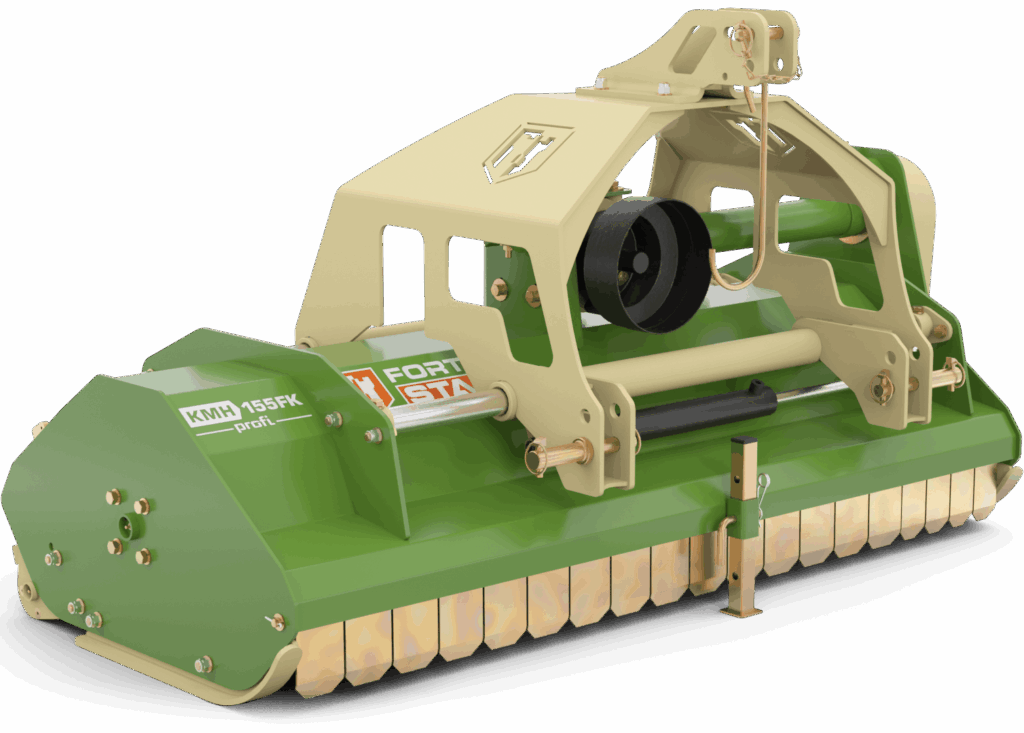

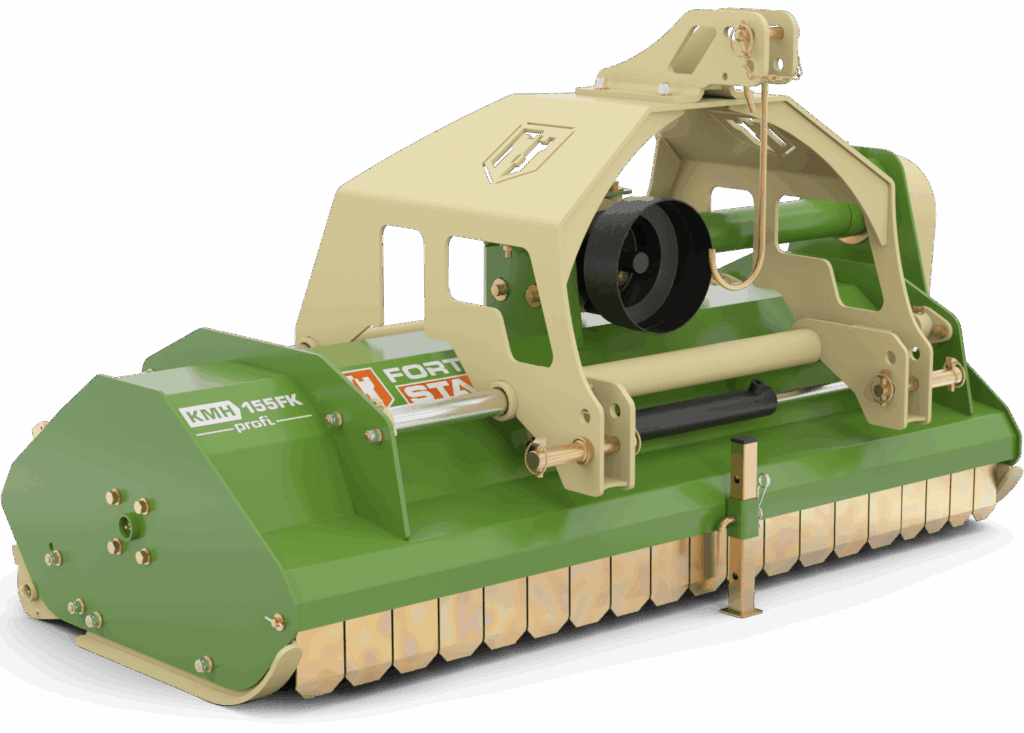

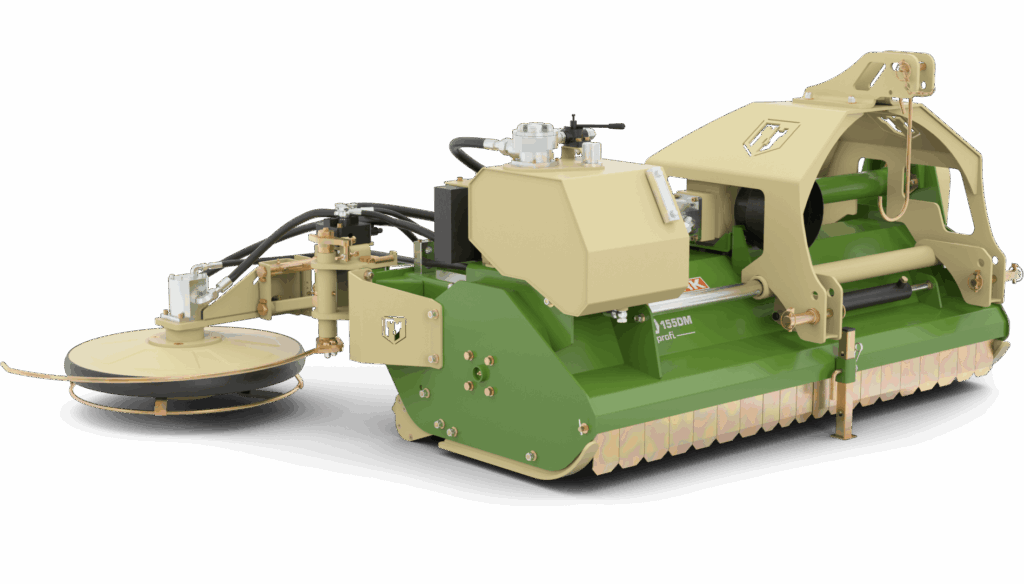

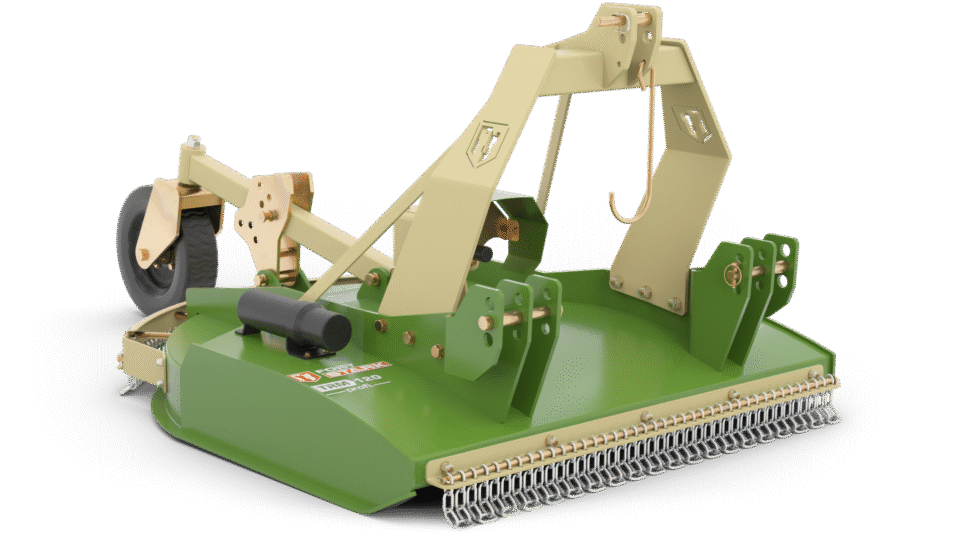

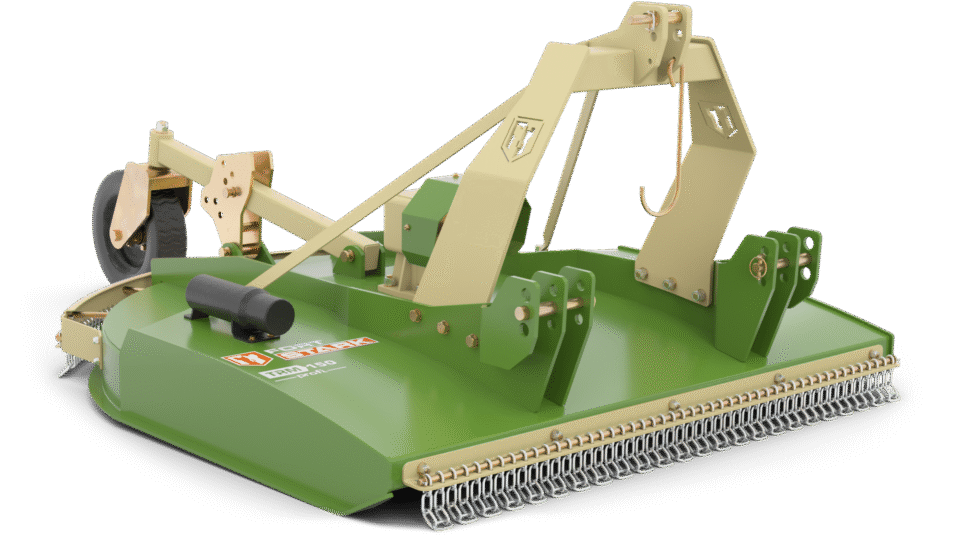

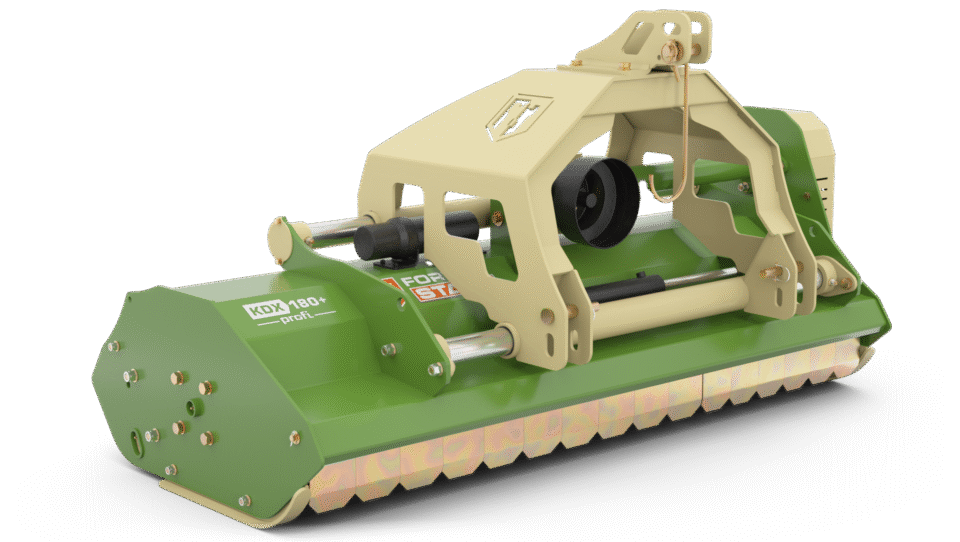

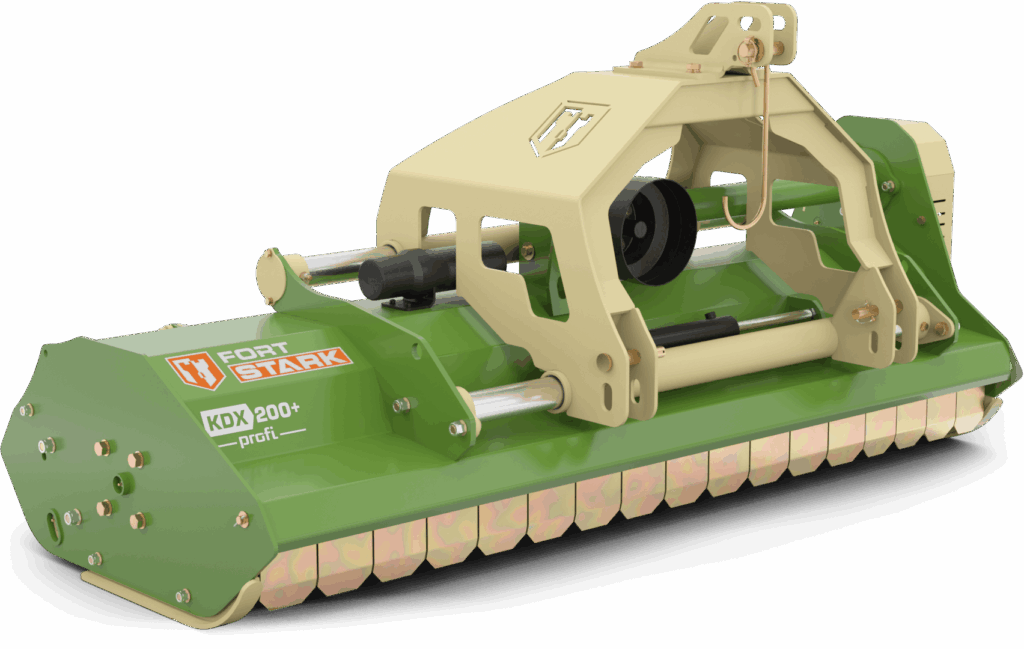

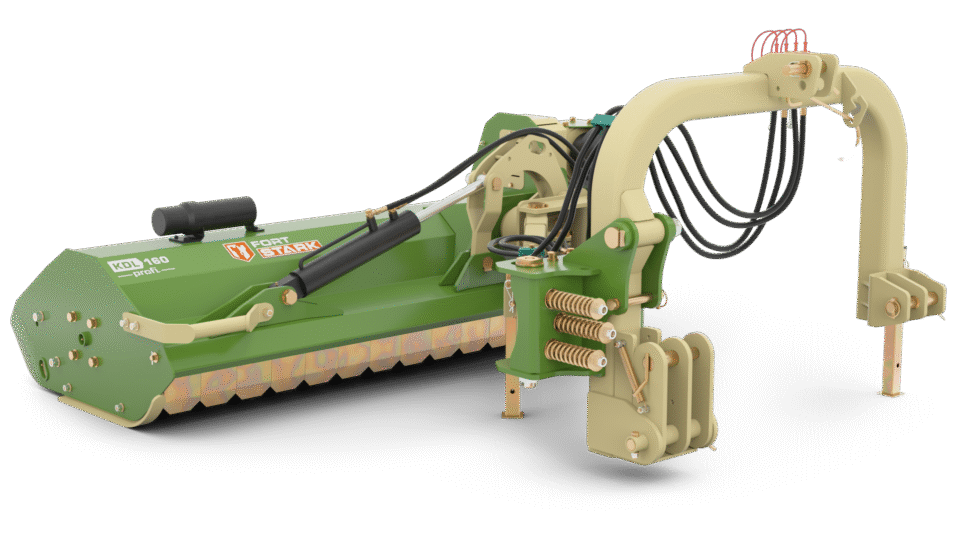

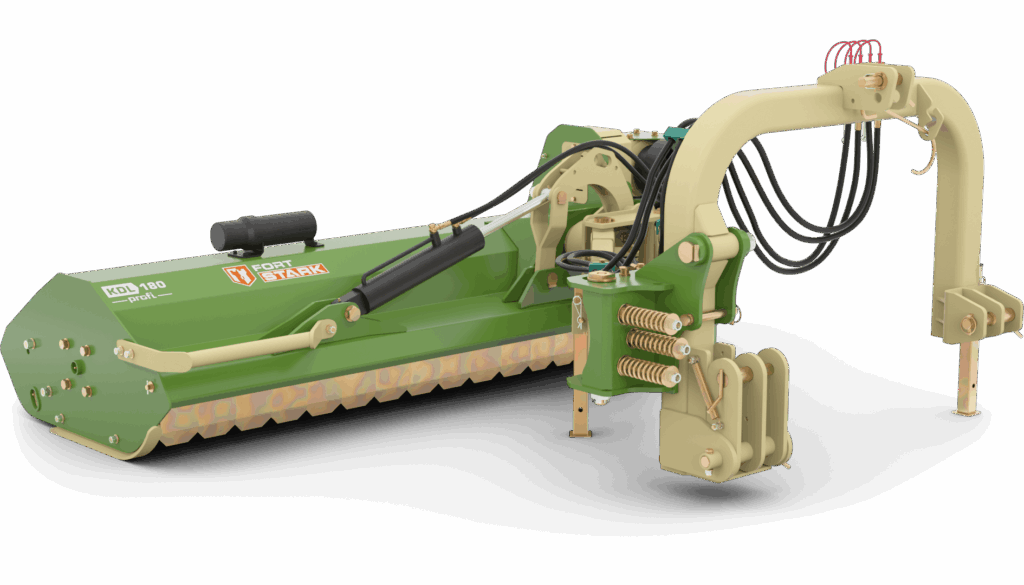

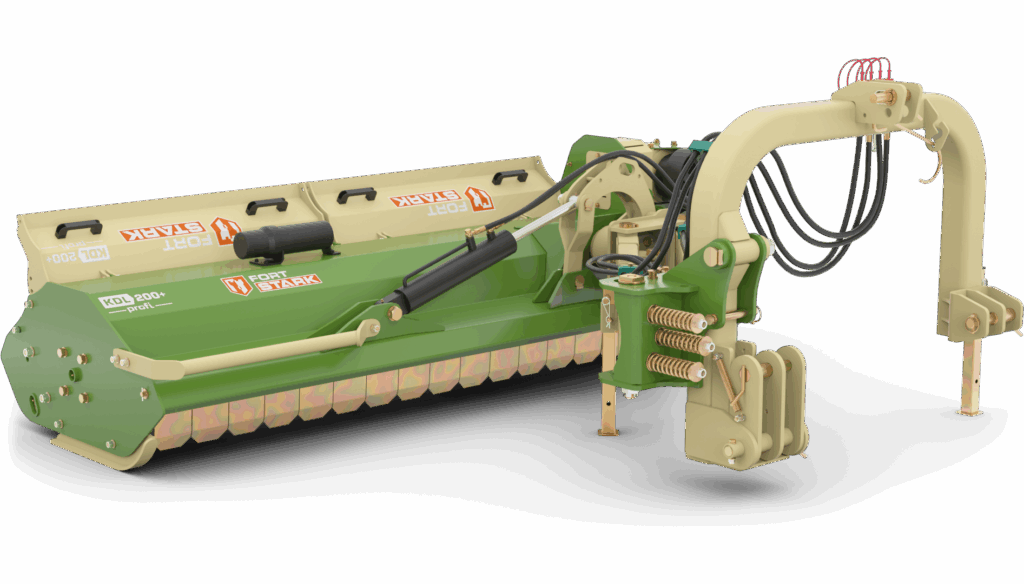

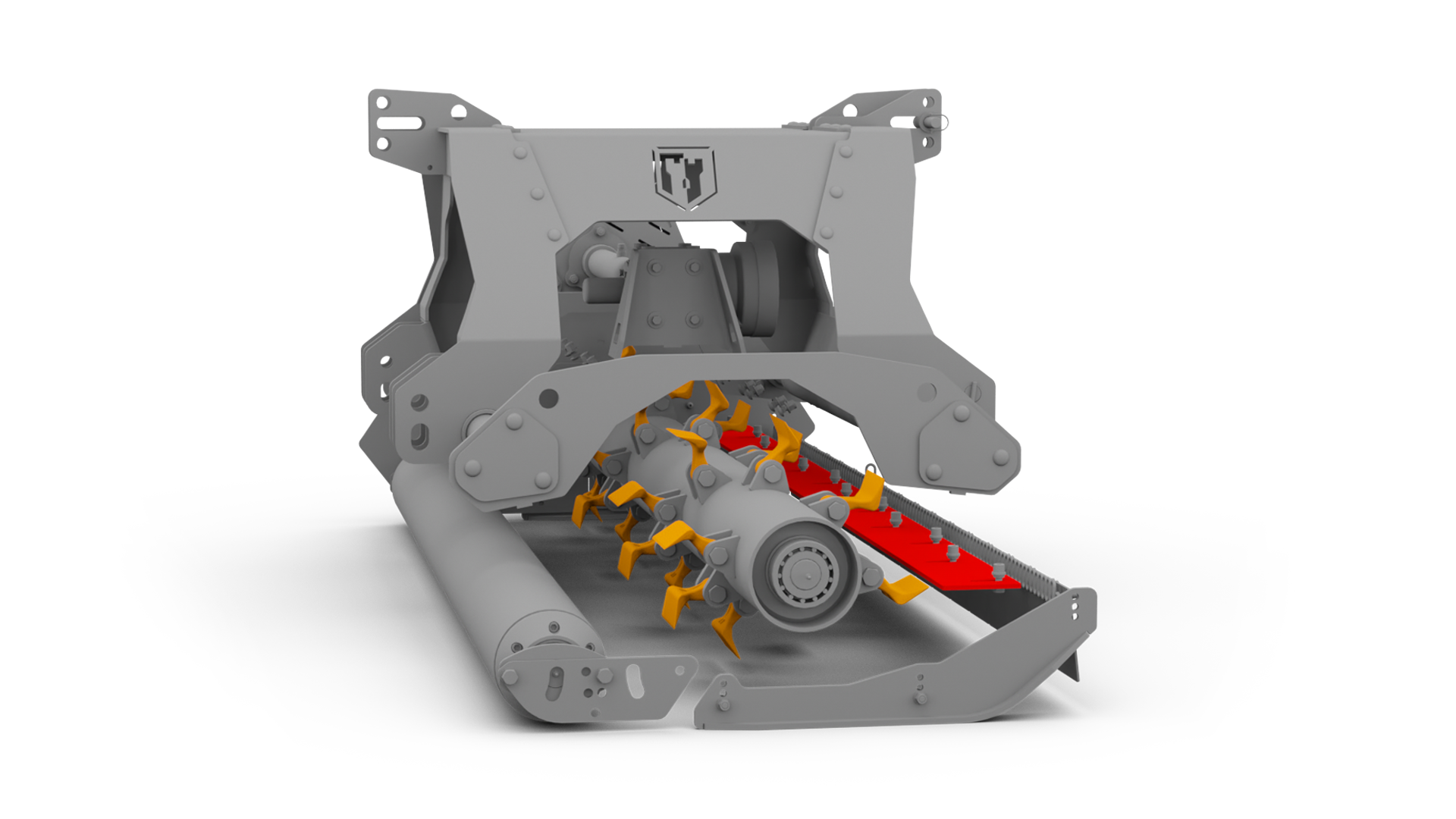

Blade-shift system cutting bar provides a precise mulching result. The smaller the clearance between the cutting bar and the rotor, the greater the suction effect. This means that even old crop residues that have previously been driven over can be processed reliably. The mulching of maize stover, for example, requires different a shredding configuration compared to the chopping of catch crops.

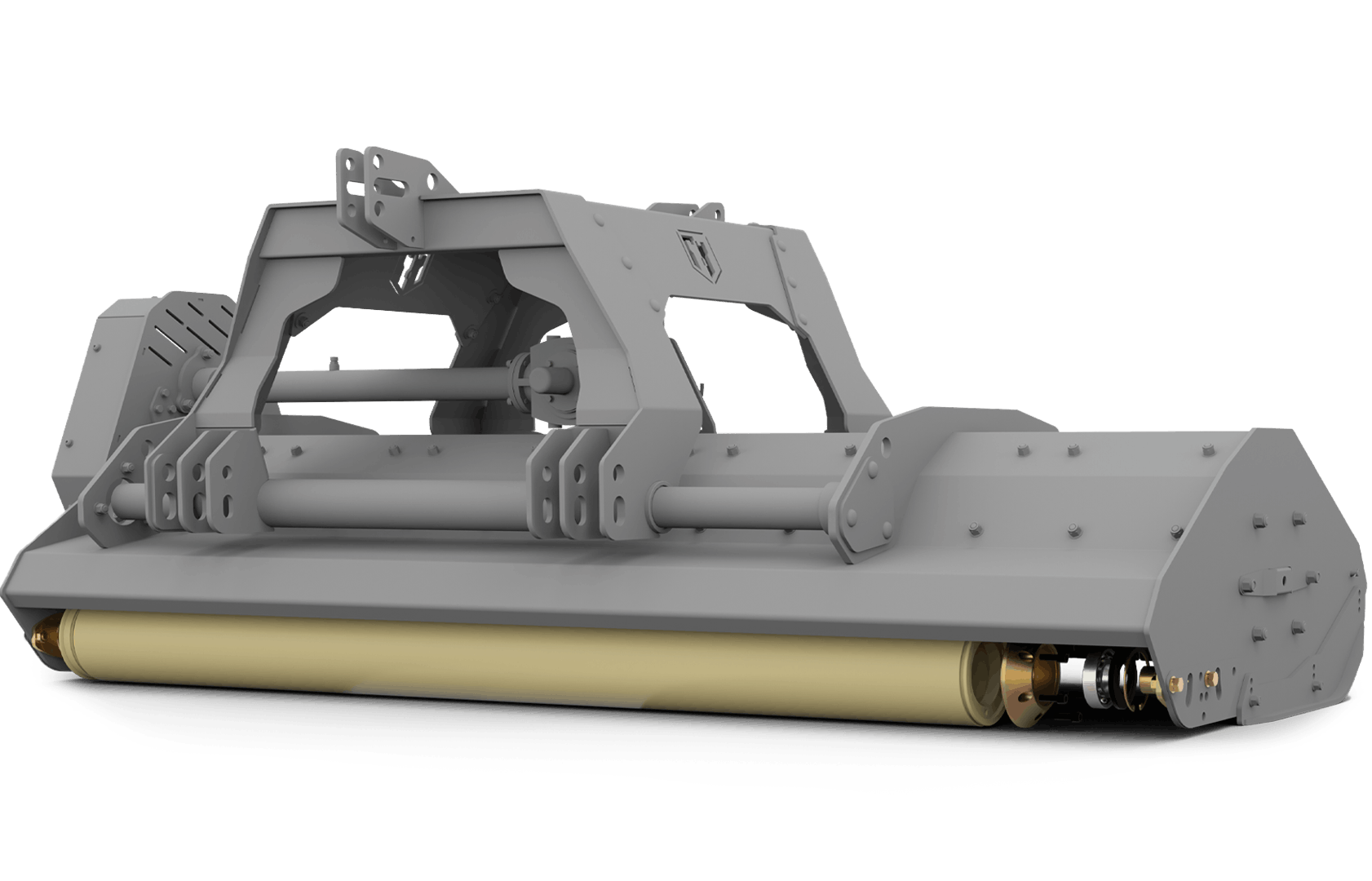

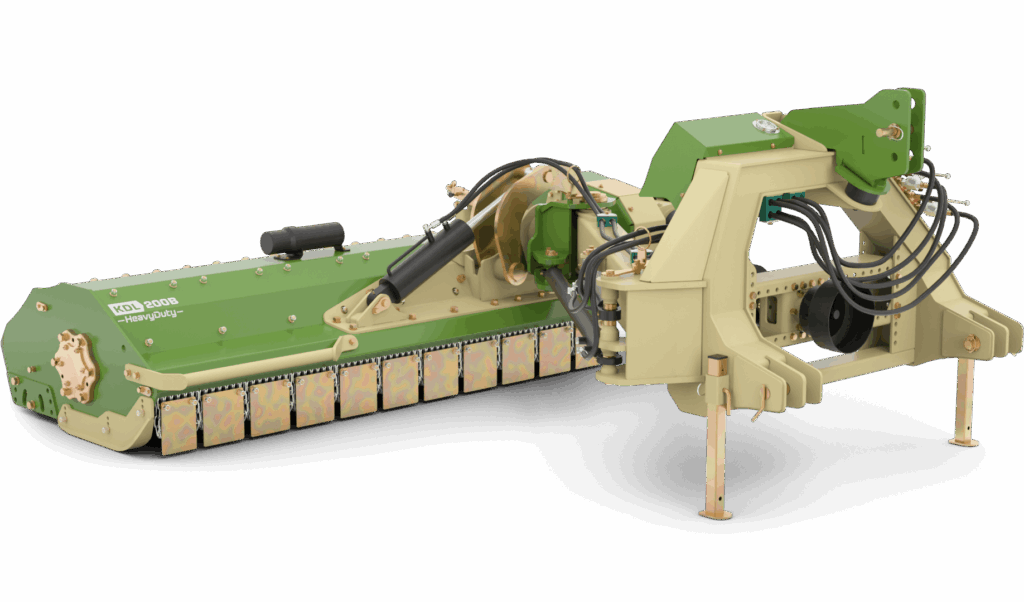

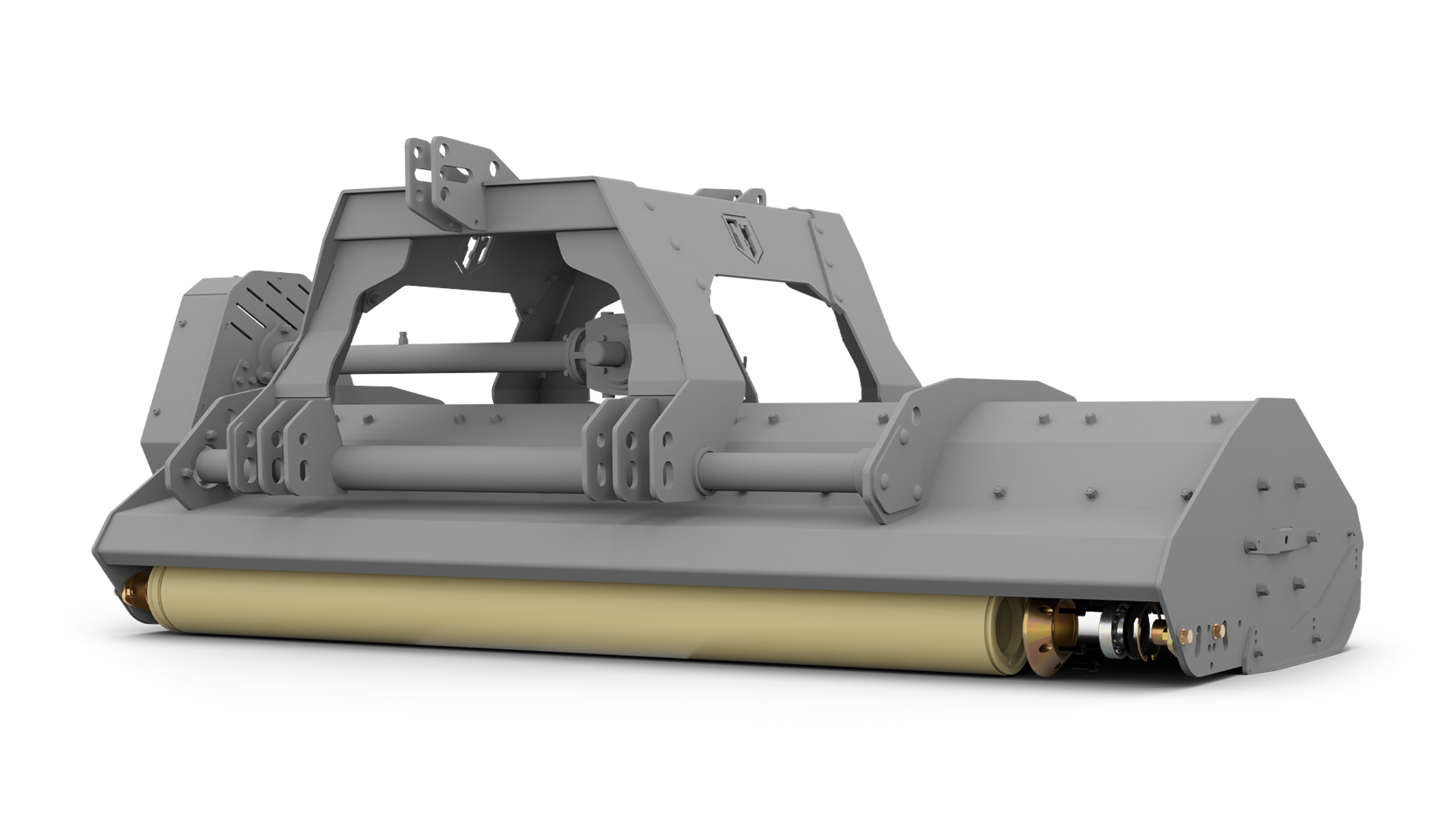

The rear roller can be adjusted to two configurations (forward and back). The former ensures a constant cutting height and self-cleaning effect, while the latter position allows the residue to be mulched into finer pieces before conveying it under the roller.

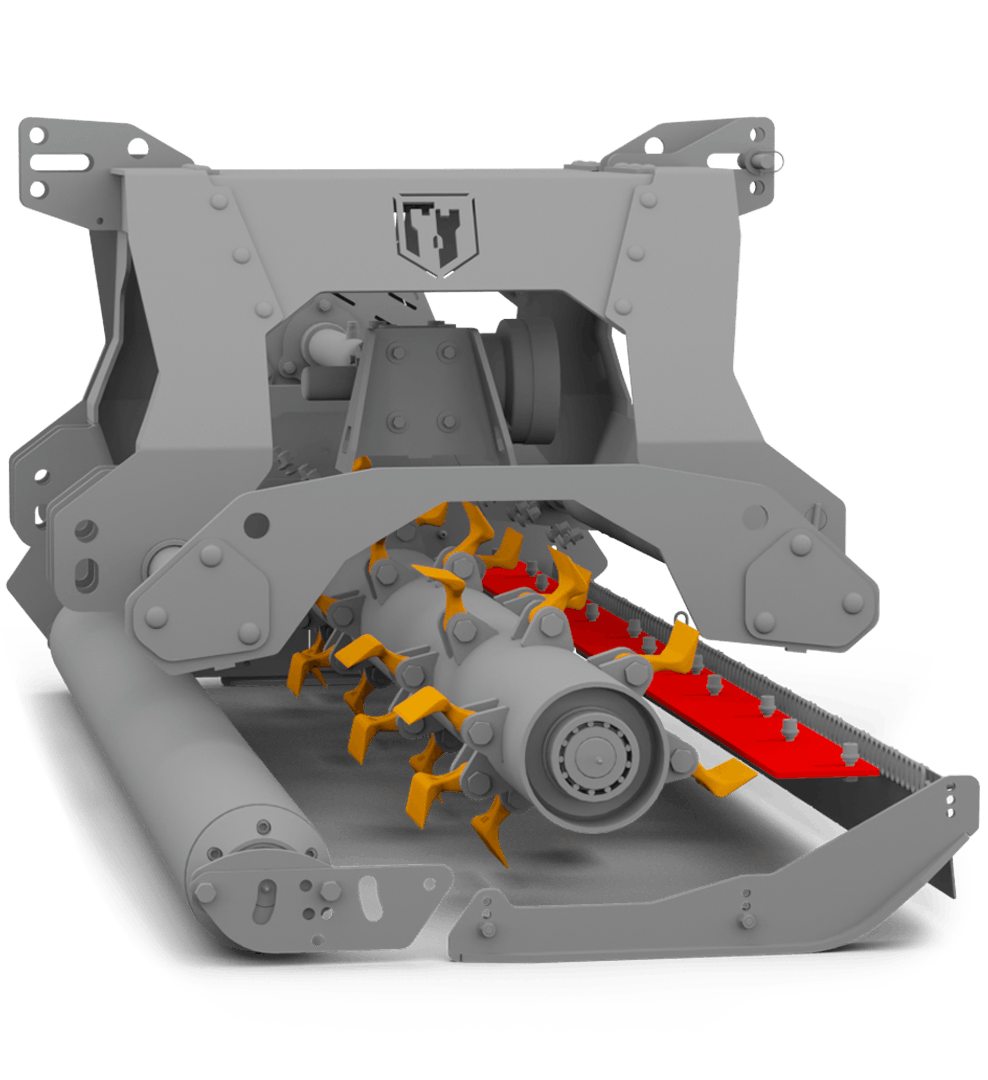

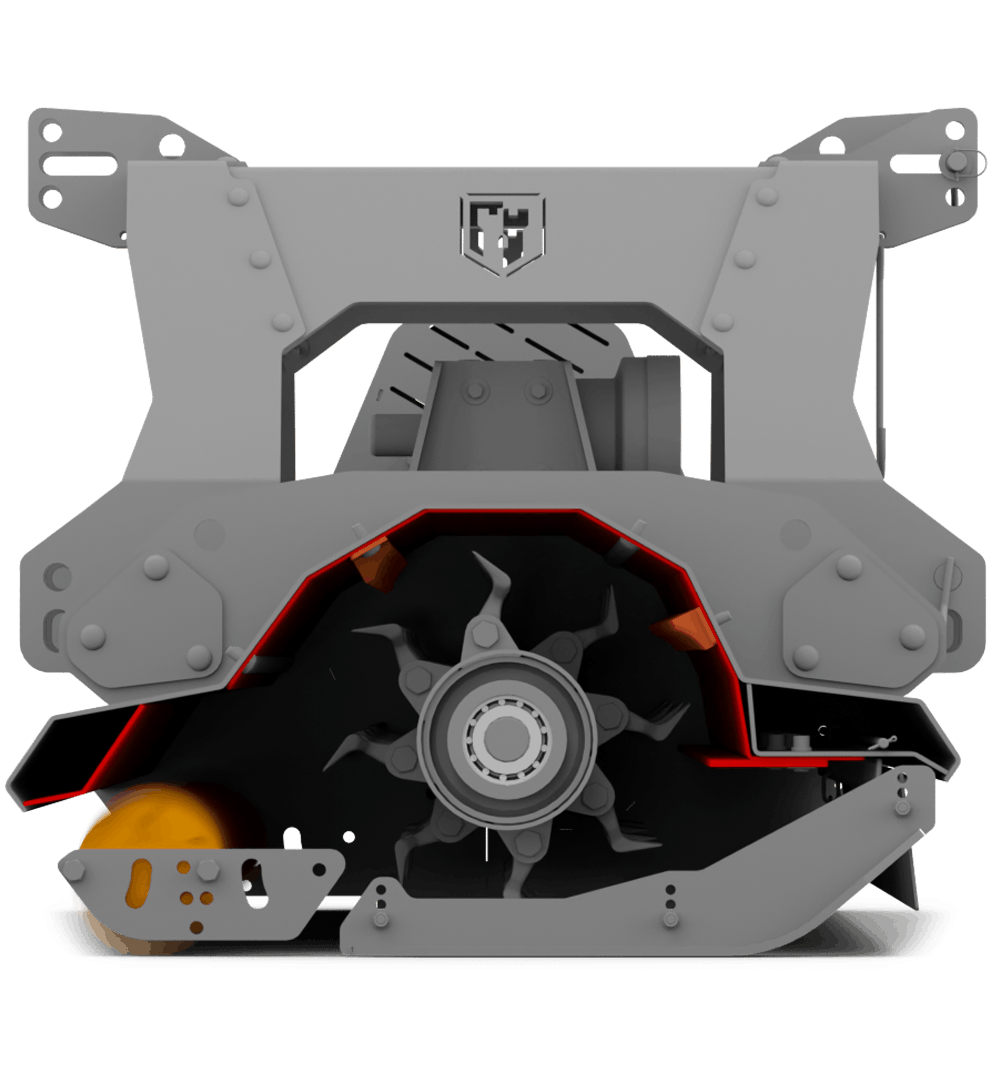

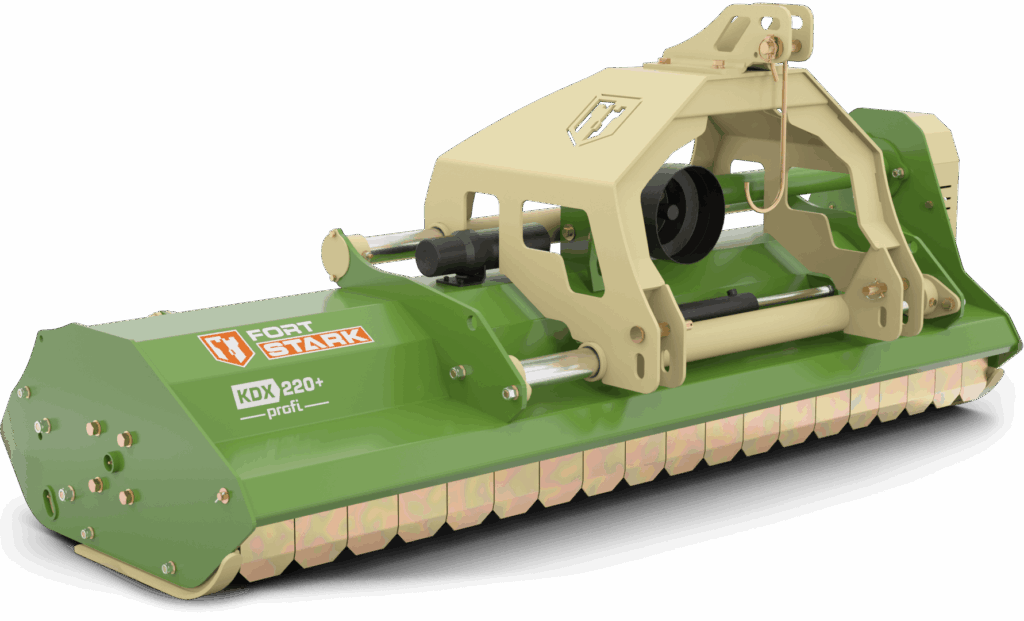

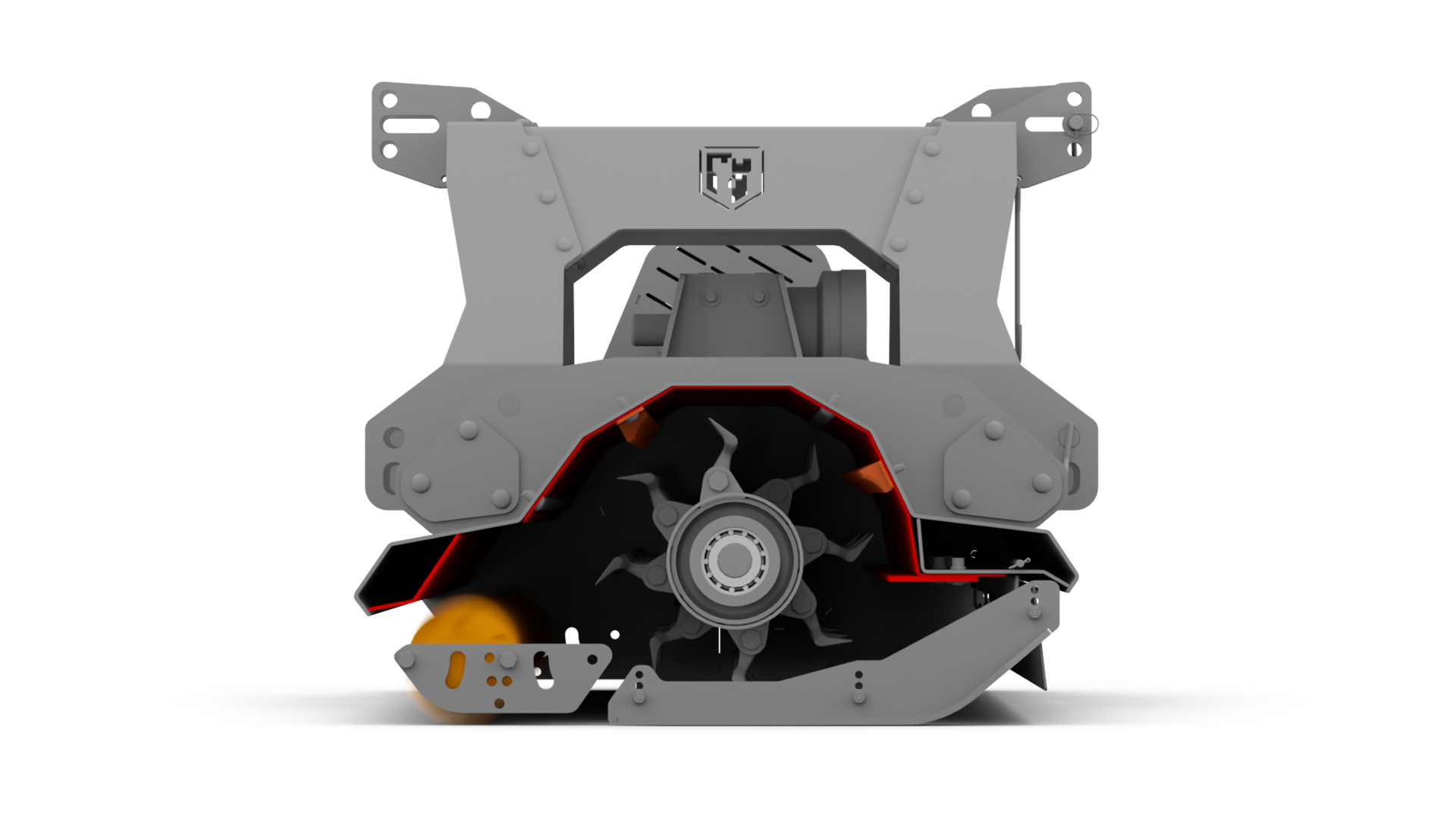

The cutting chamber on features a double-skinned construction (6 + 4 mm) The toothed counter blades allow the machine to mulch even the more voluminous residues and thicker branches into fine pieces. The body is reinforced with the addition of a sheet metal internal housing for extra strength.

Two counter-knives with a self-cleaning and exchangeable design. These ensure uniform shredding of all of the material. Long material is fed through the rotor in a second step in the crop flow, whereas material that is already shredded passes through. The result is homogenous mulched material.

Roller of 195 mm with removable ends. Seal to protect the life-greased bearings.

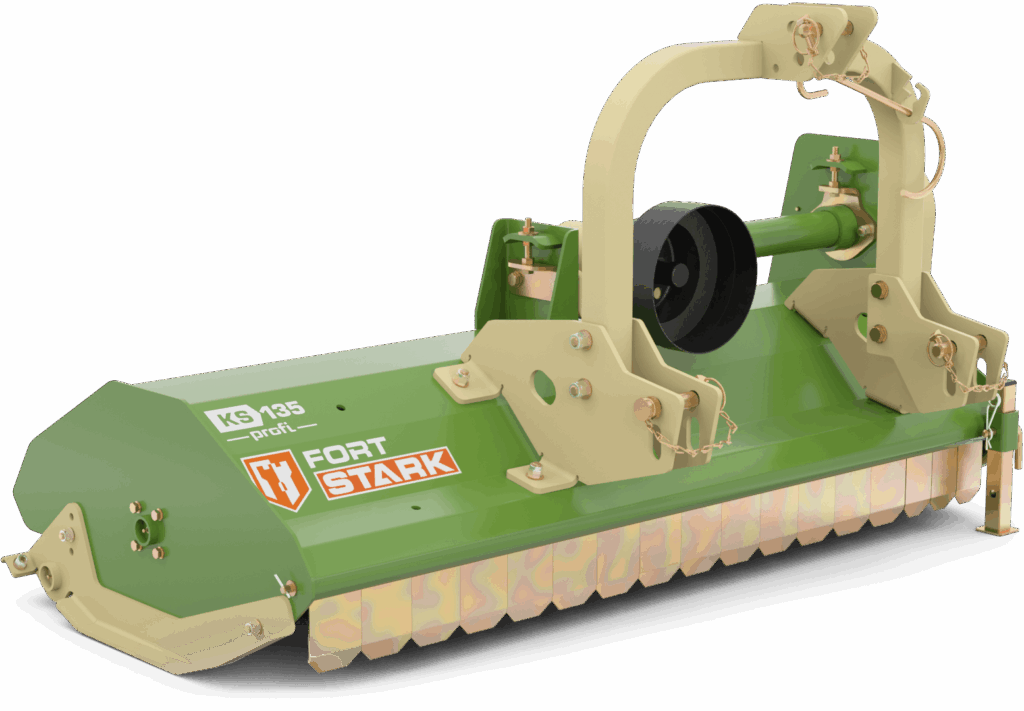

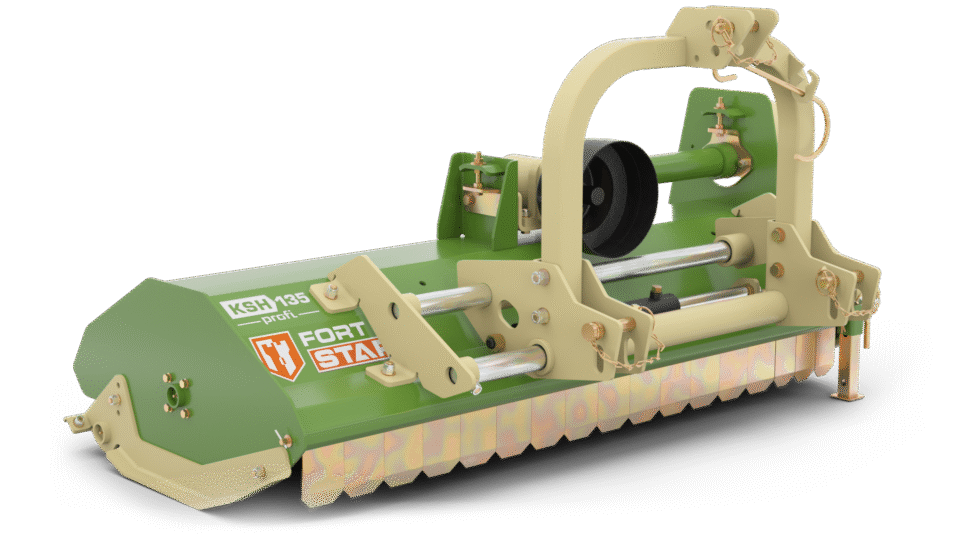

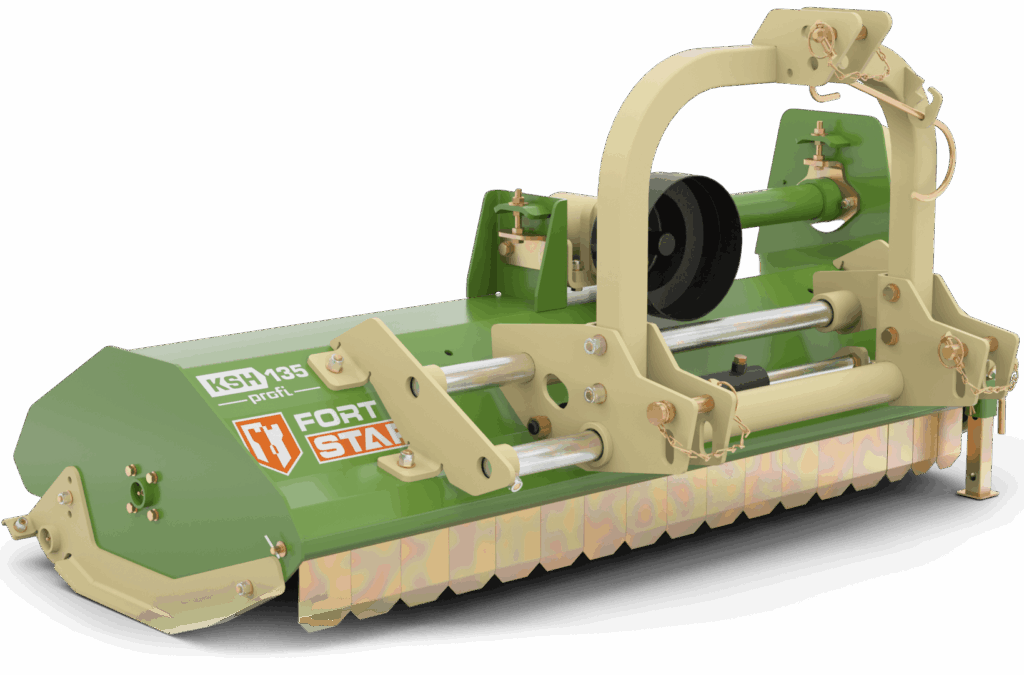

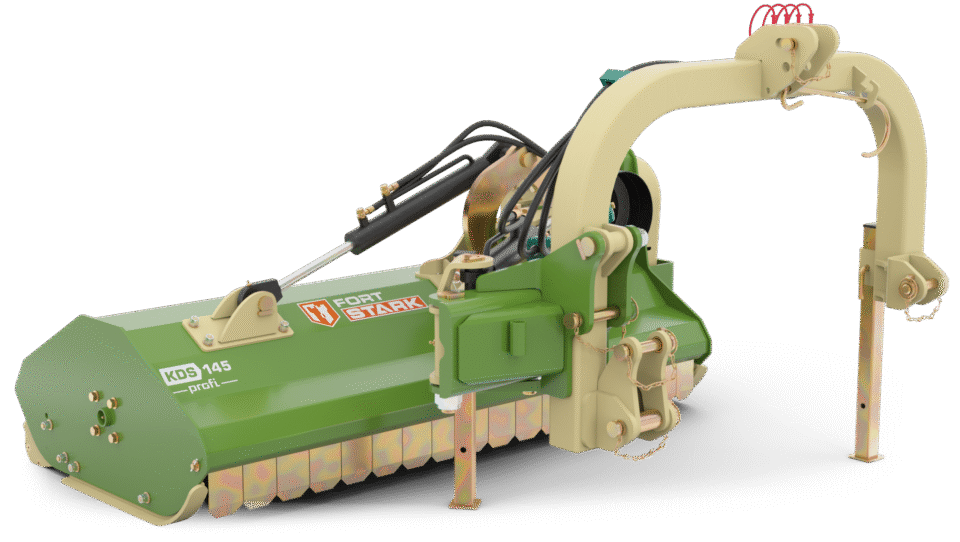

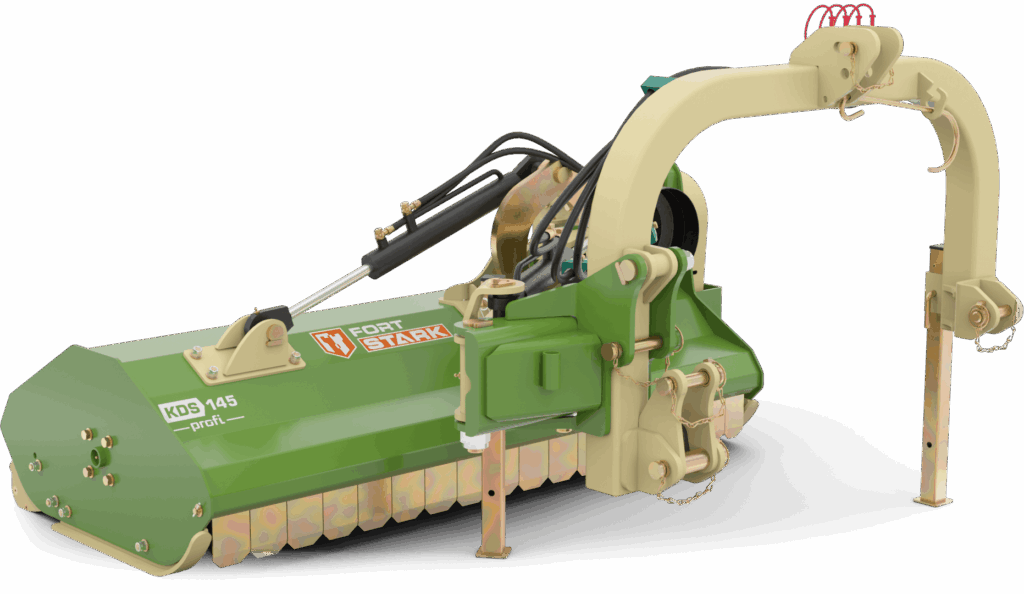

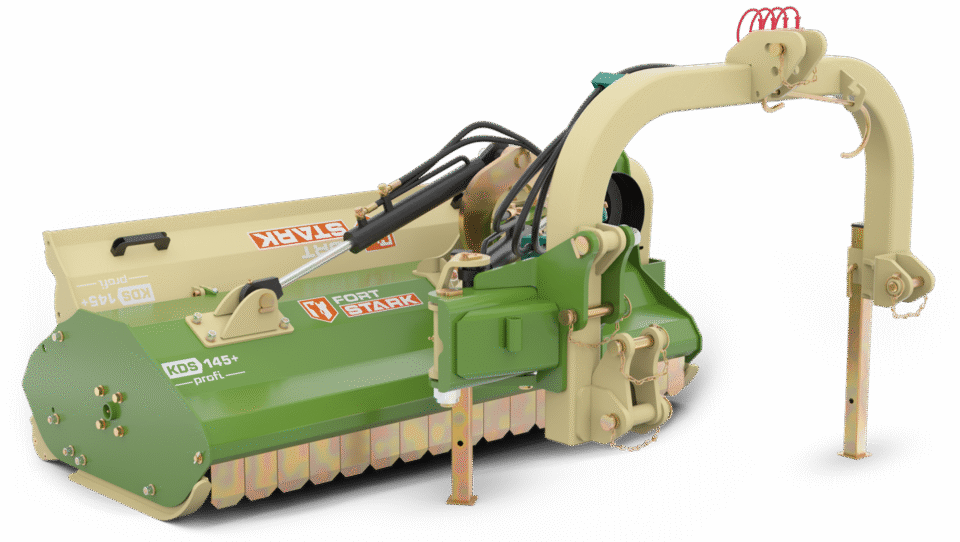

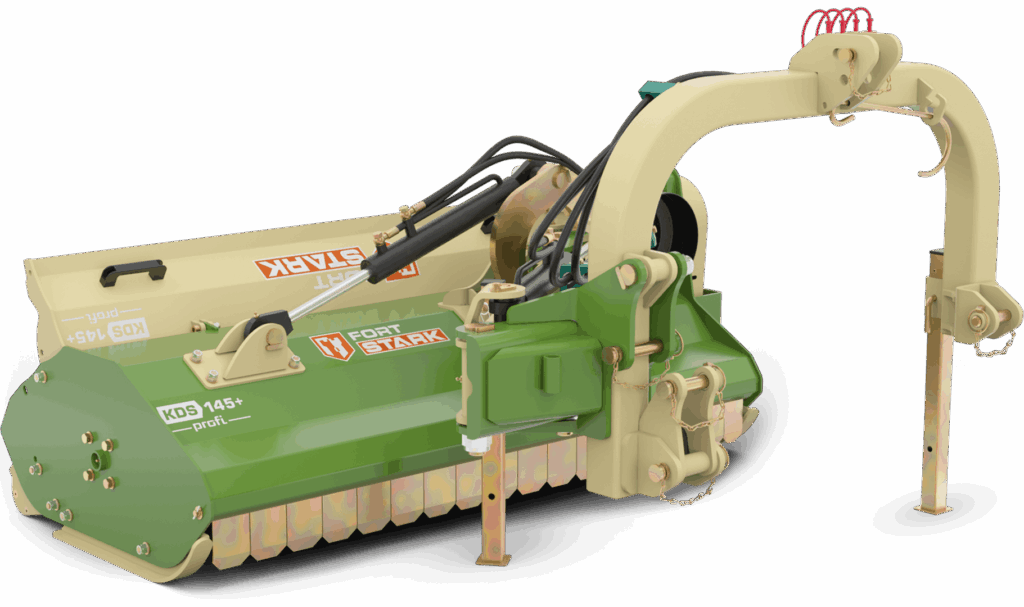

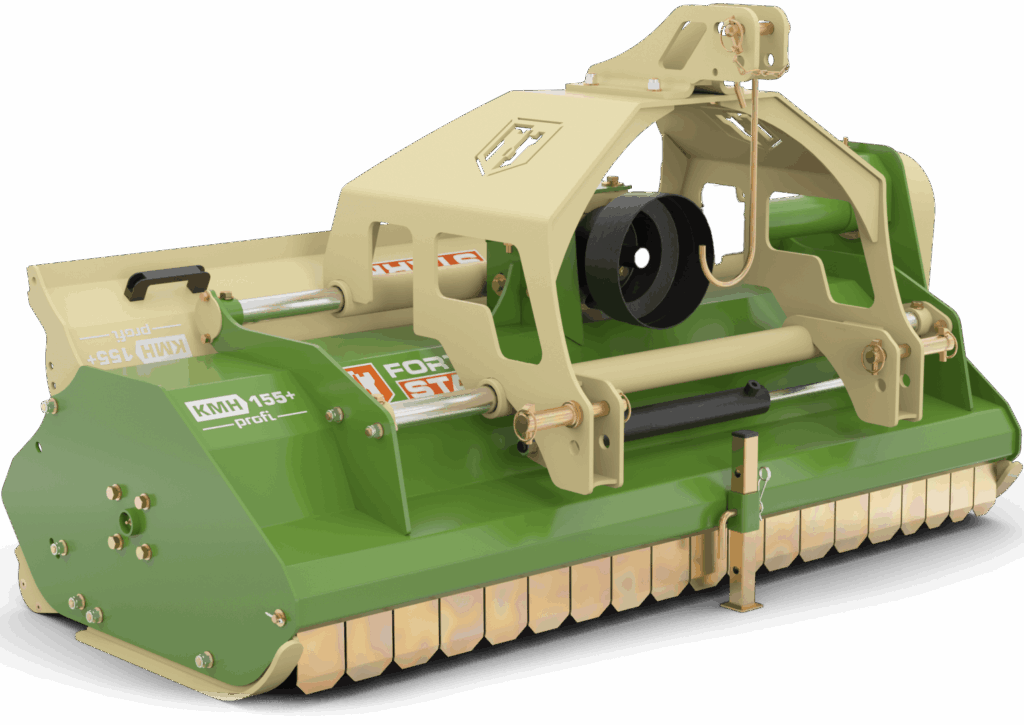

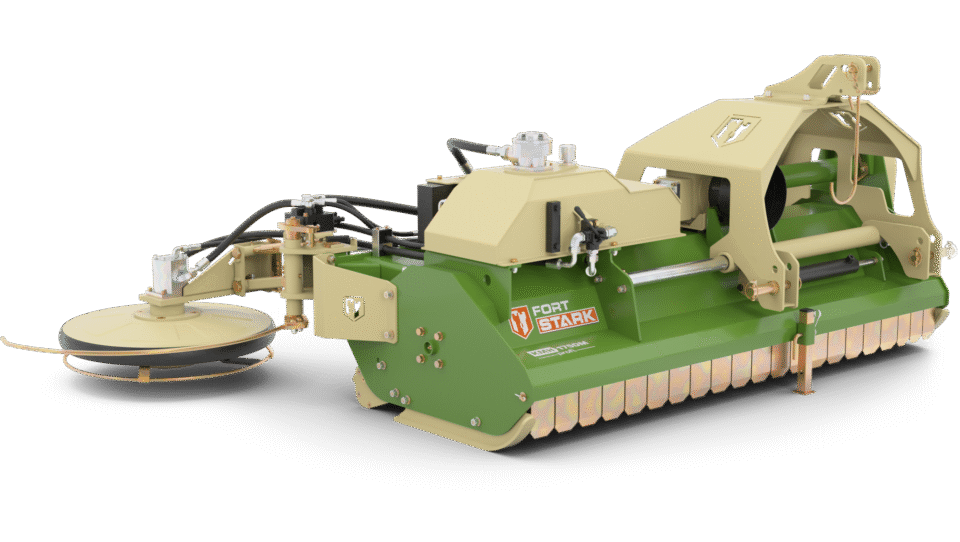

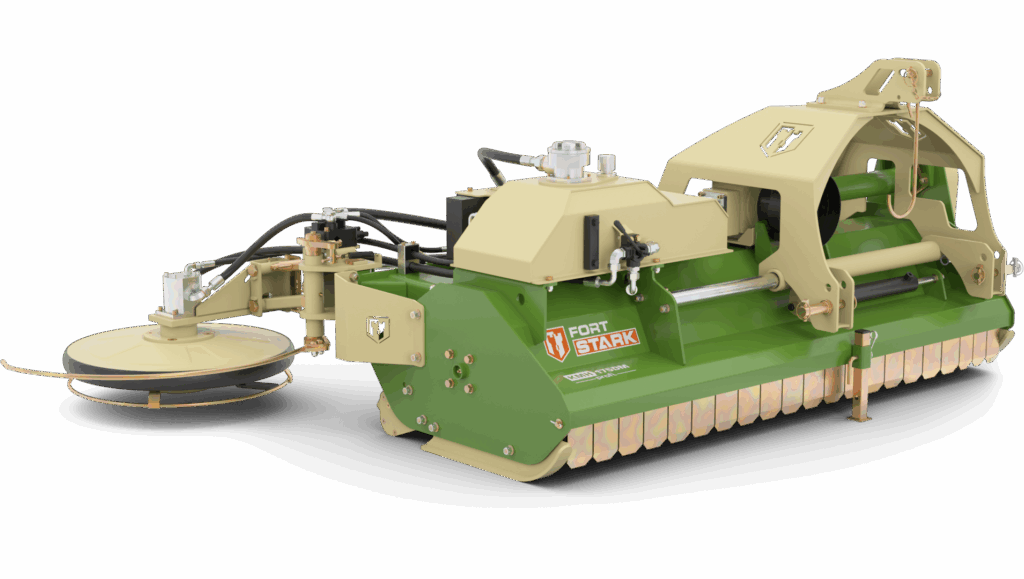

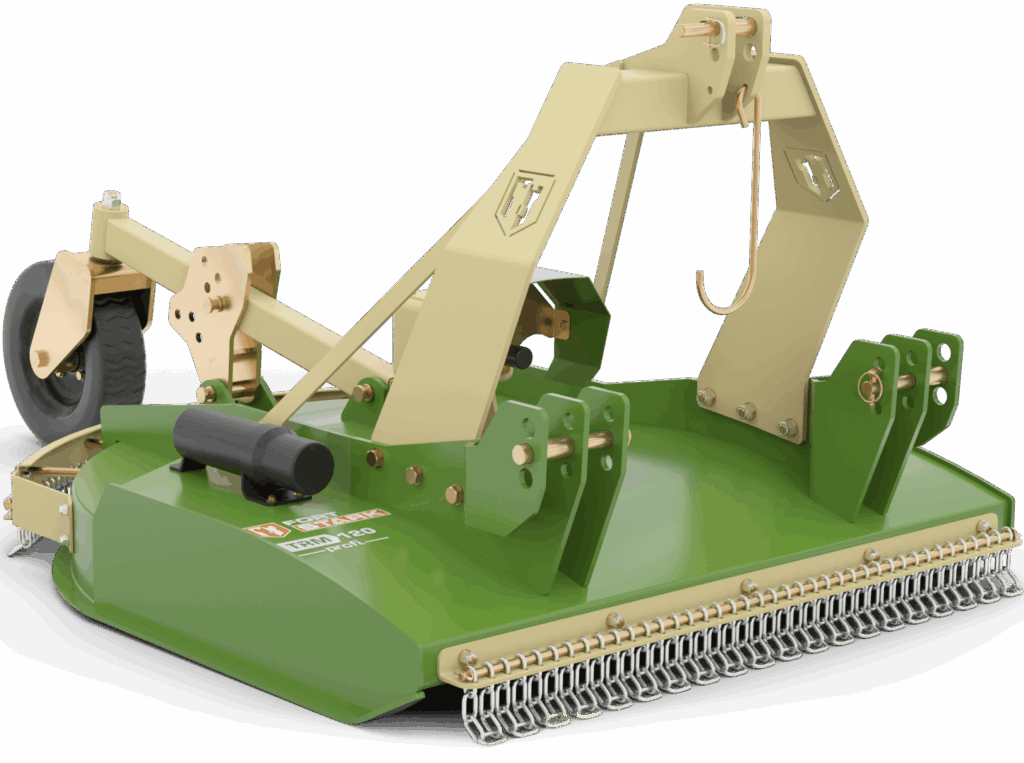

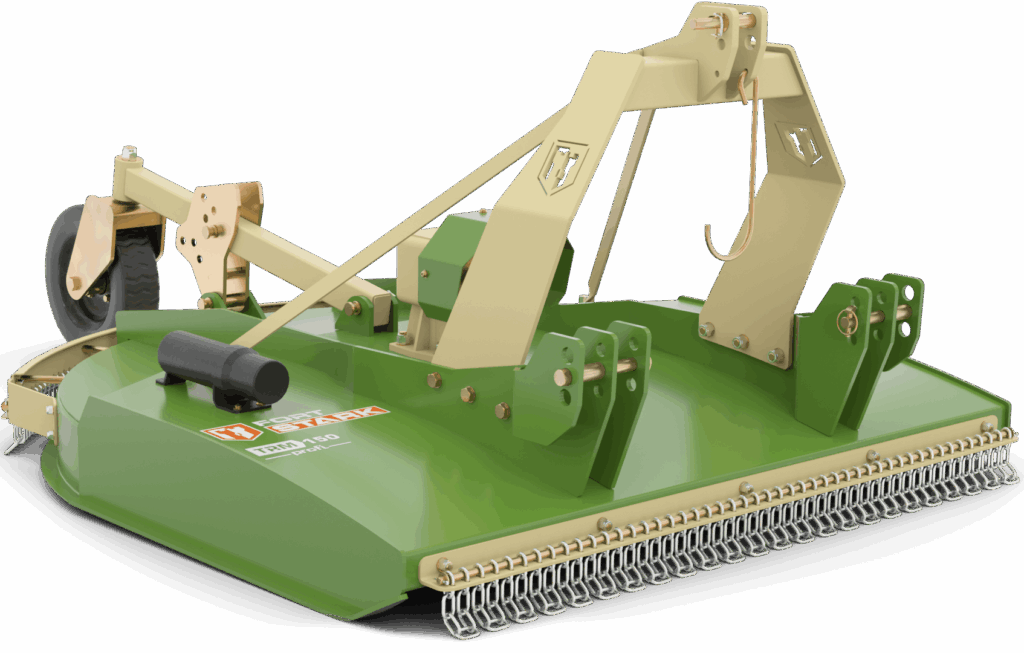

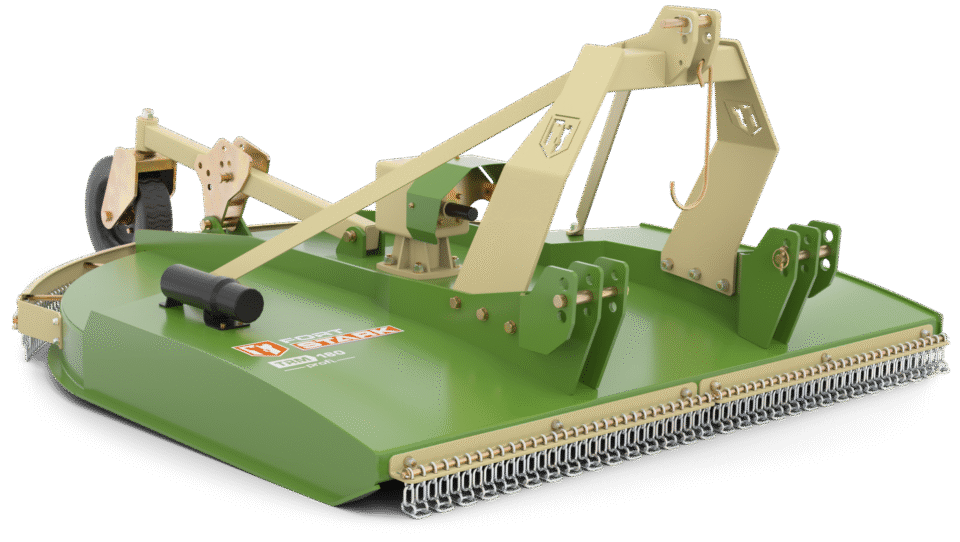

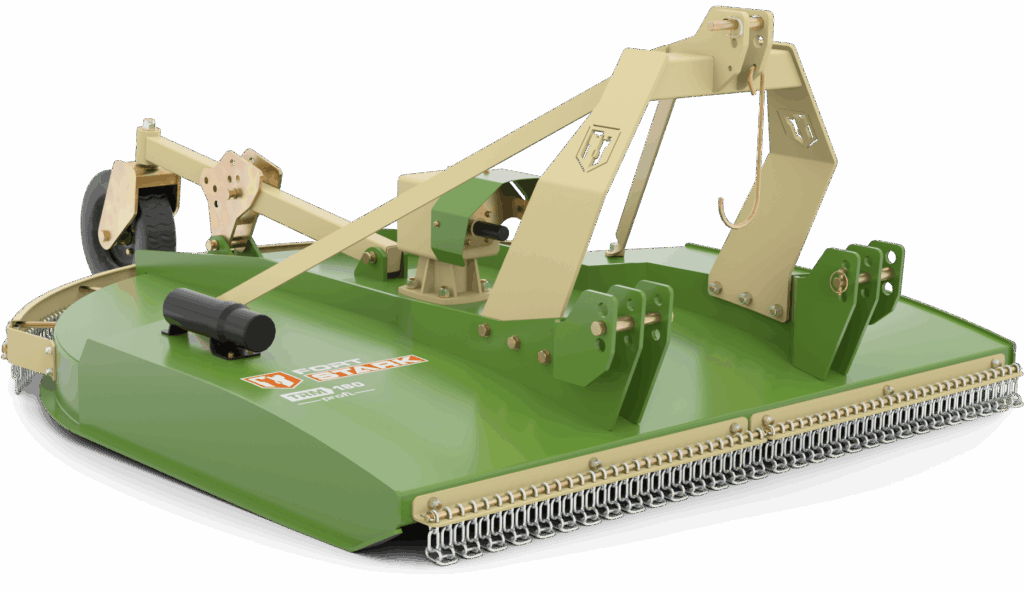

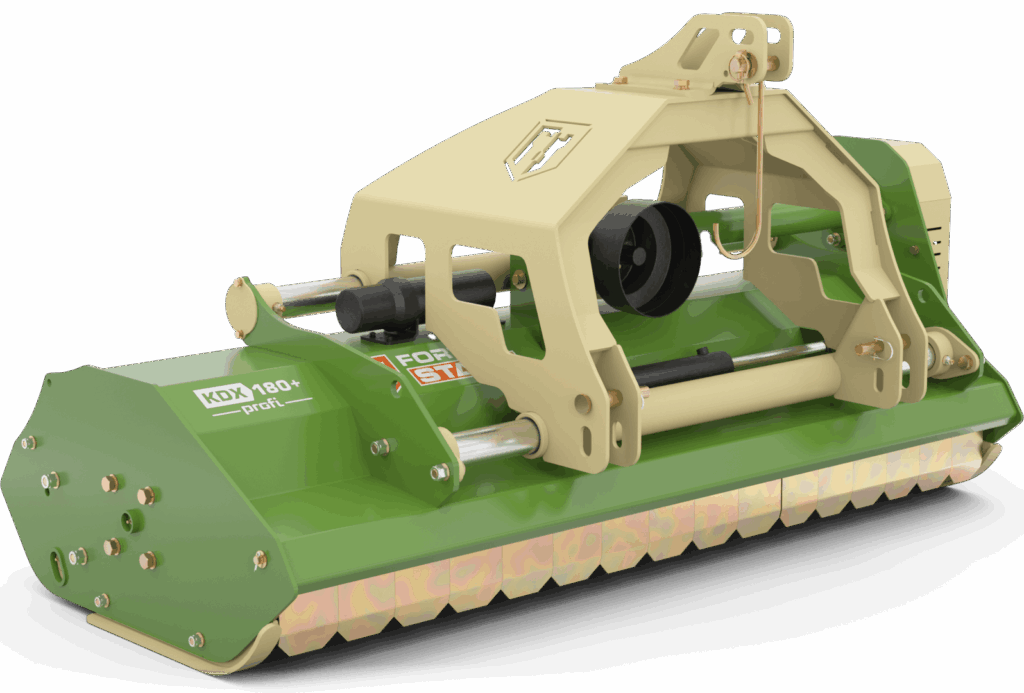

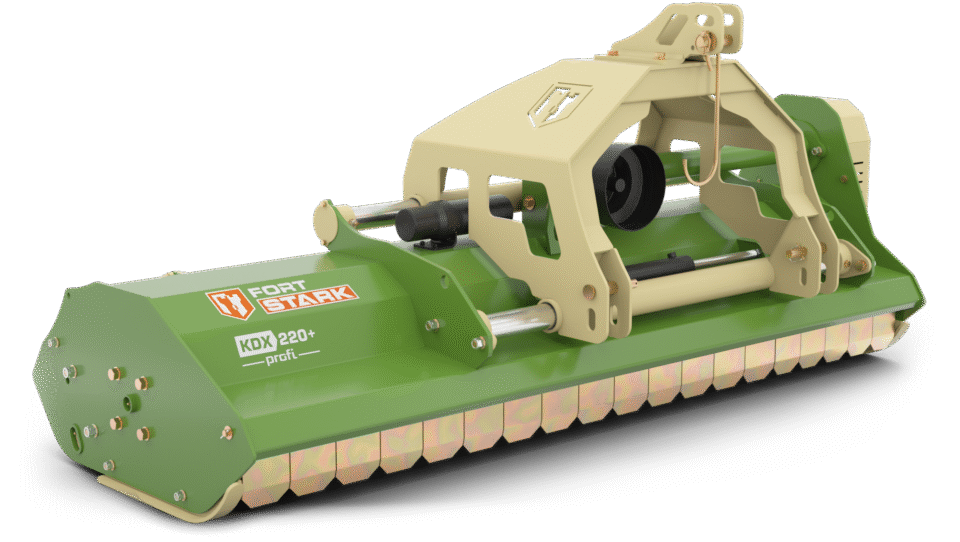

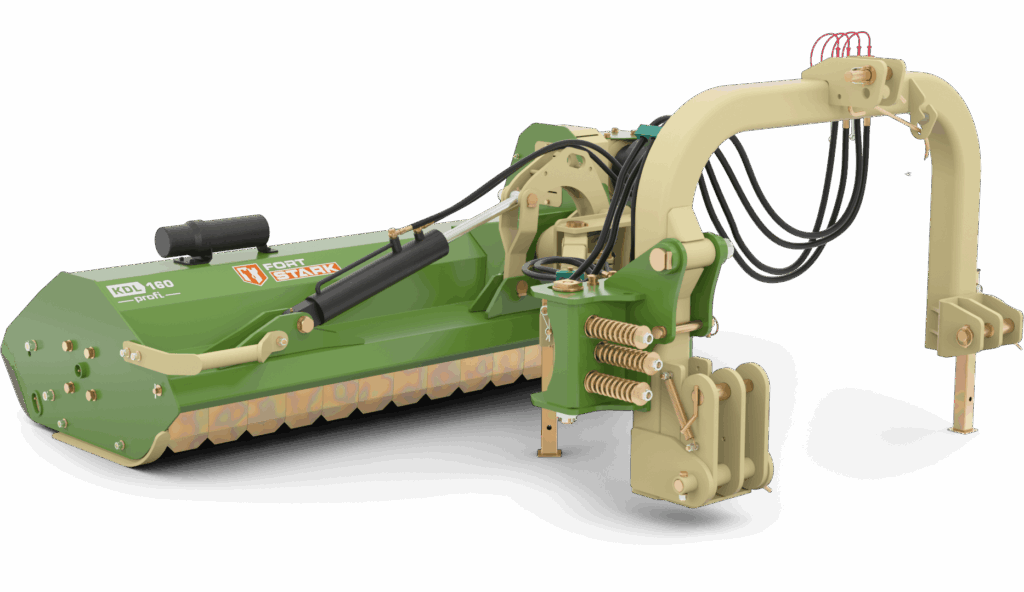

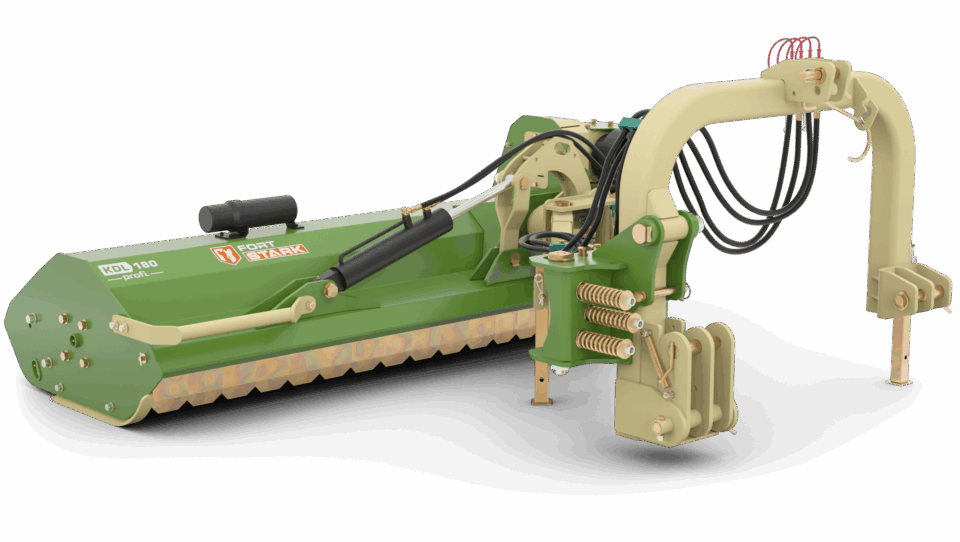

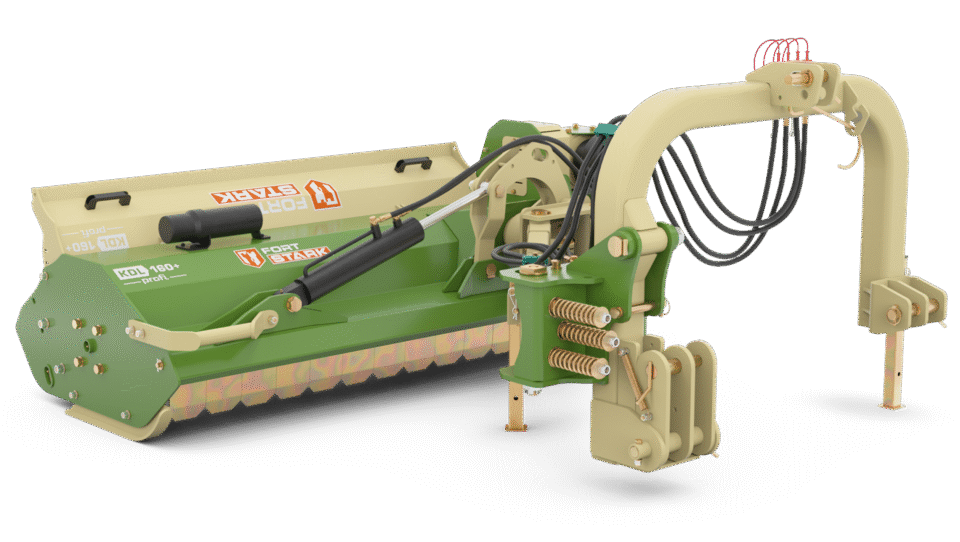

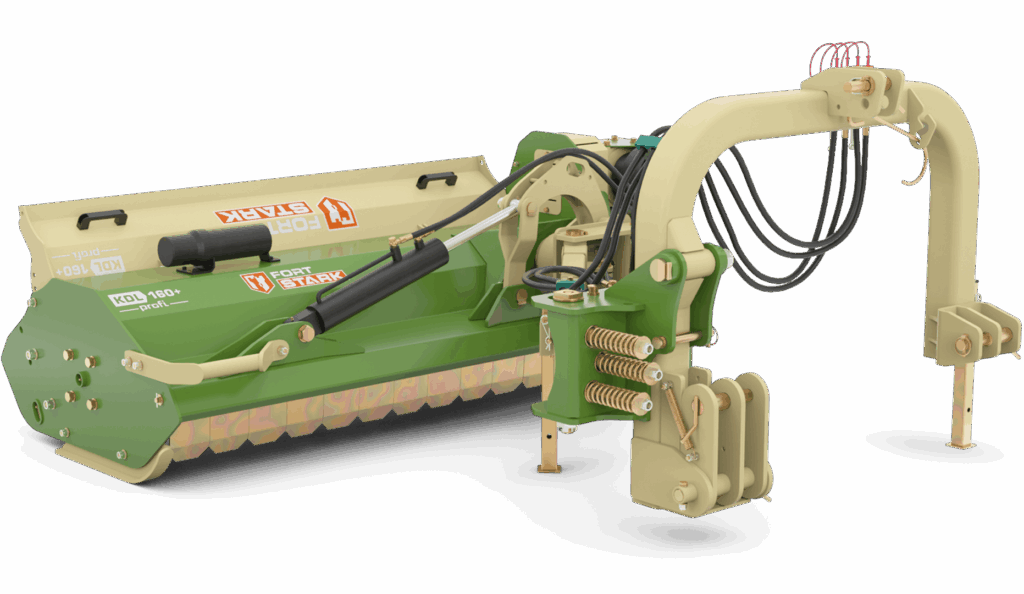

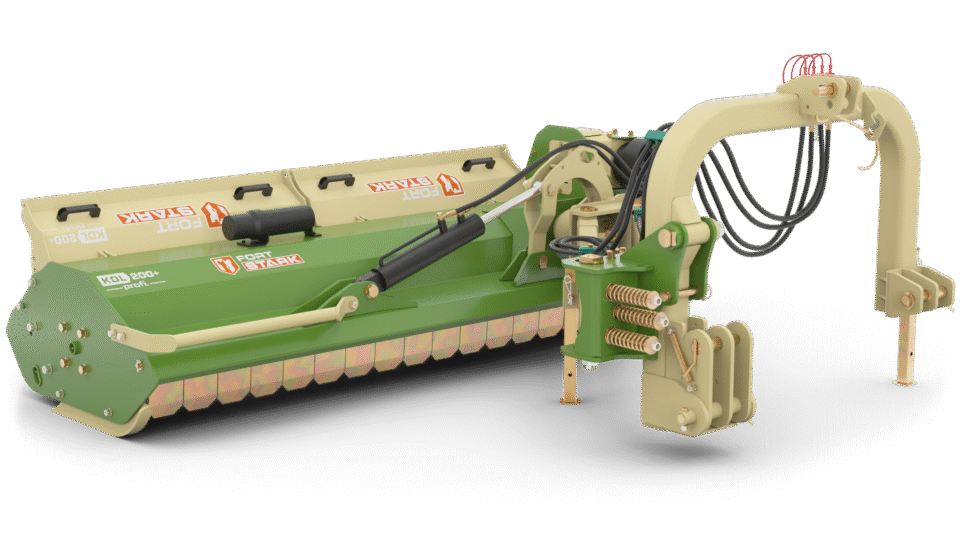

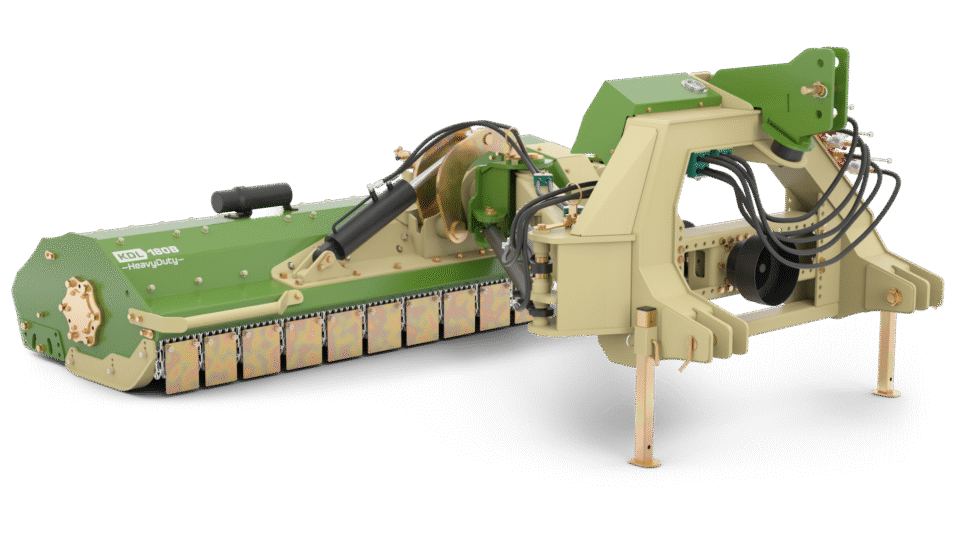

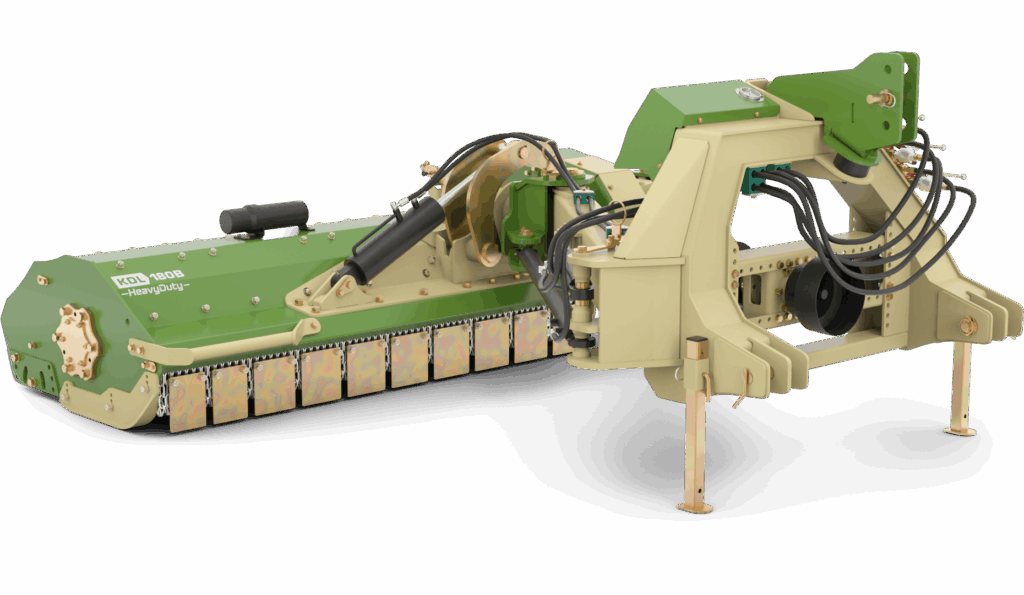

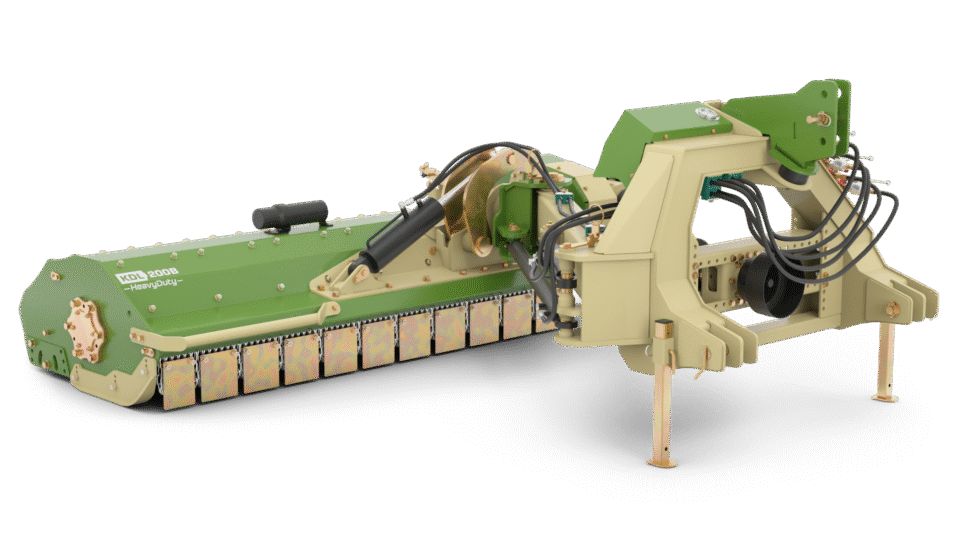

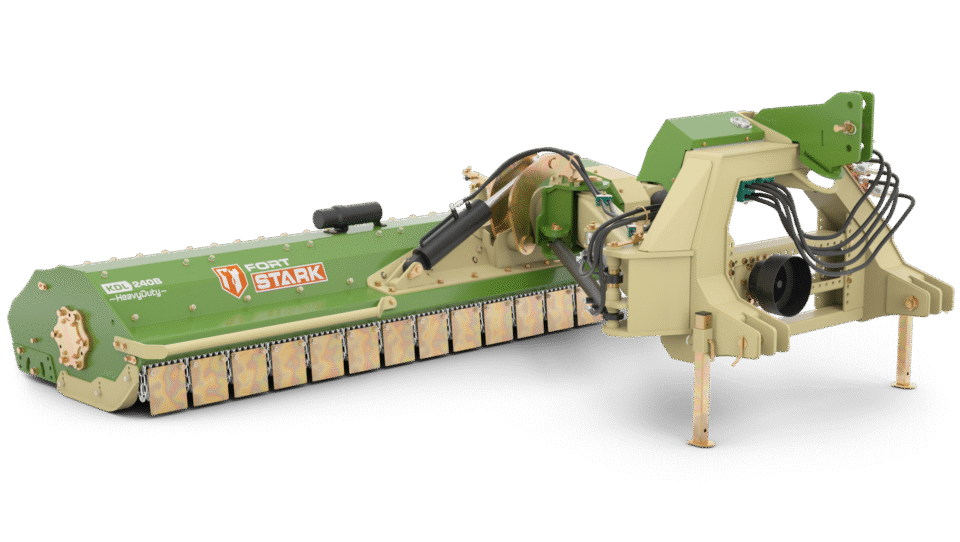

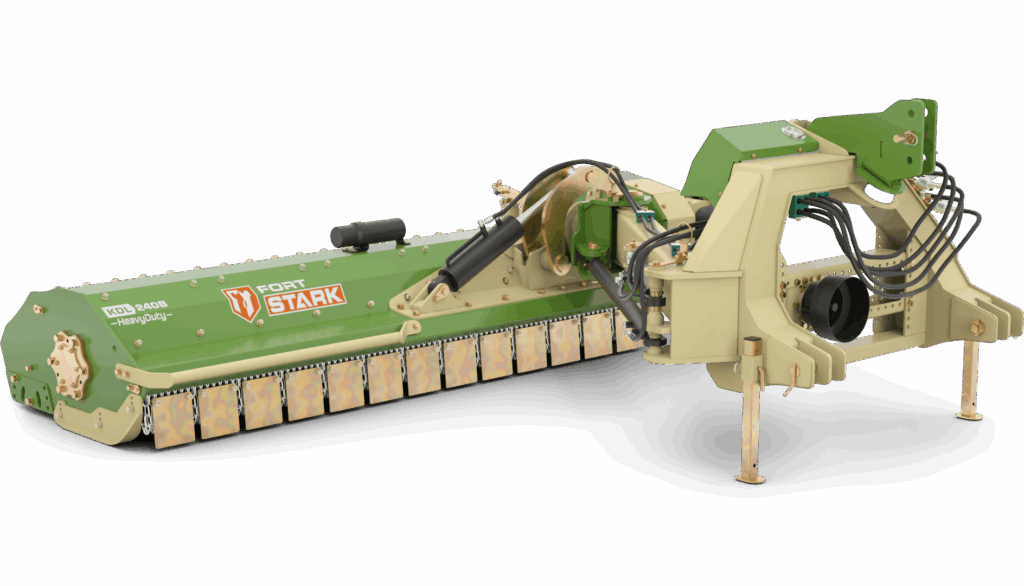

Blade-shift system cutting bar provides a precise mulching result. The smaller the clearance between the cutting bar and the rotor, the greater the suction effect. This means that even old crop residues that have previously been driven over can be processed reliably. The mulching of maize stover, for example, requires different a shredding configuration compared to the chopping of catch crops.

The rear roller can be adjusted to two configurations (forward and back). The former ensures a constant cutting height and self-cleaning effect, while the latter position allows the residue to be mulched into finer pieces before conveying it under the roller.

The cutting chamber on features a double-skinned construction (6 + 4 mm) The toothed counter blades allow the machine to mulch even the more voluminous residues and thicker branches into fine pieces. The body is reinforced with the addition of a sheet metal internal housing for extra strength.

Two counter-knives with a self-cleaning and exchangeable design. These ensure uniform shredding of all of the material. Long material is fed through the rotor in a second step in the crop flow, whereas material that is already shredded passes through. The result is homogenous mulched material.