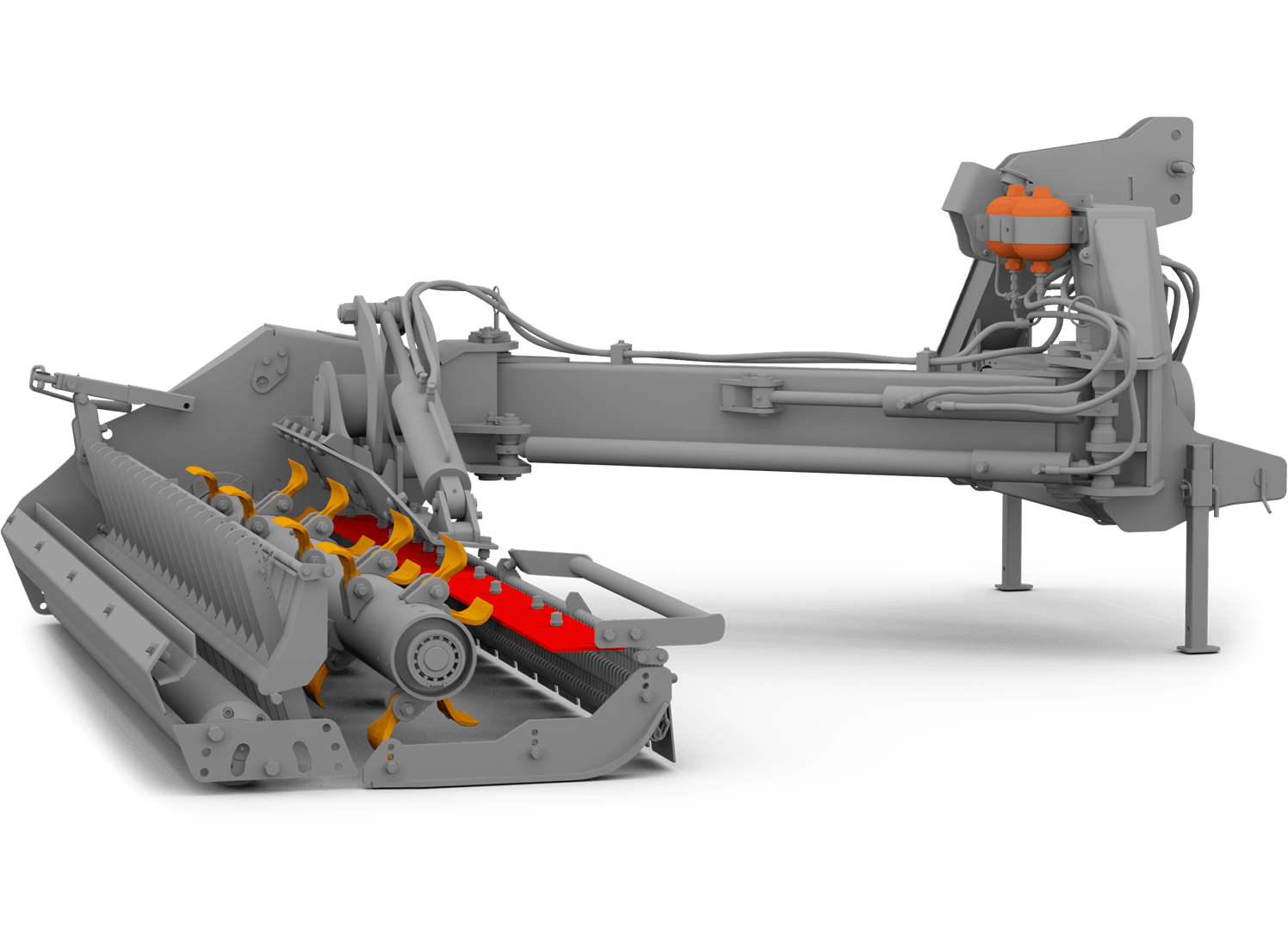

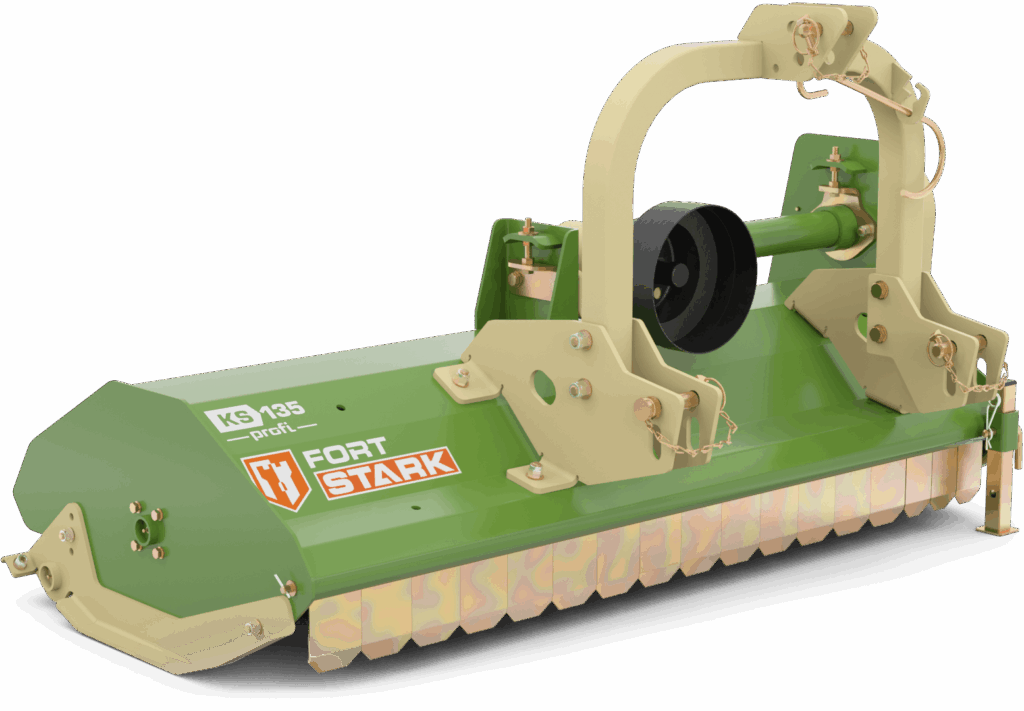

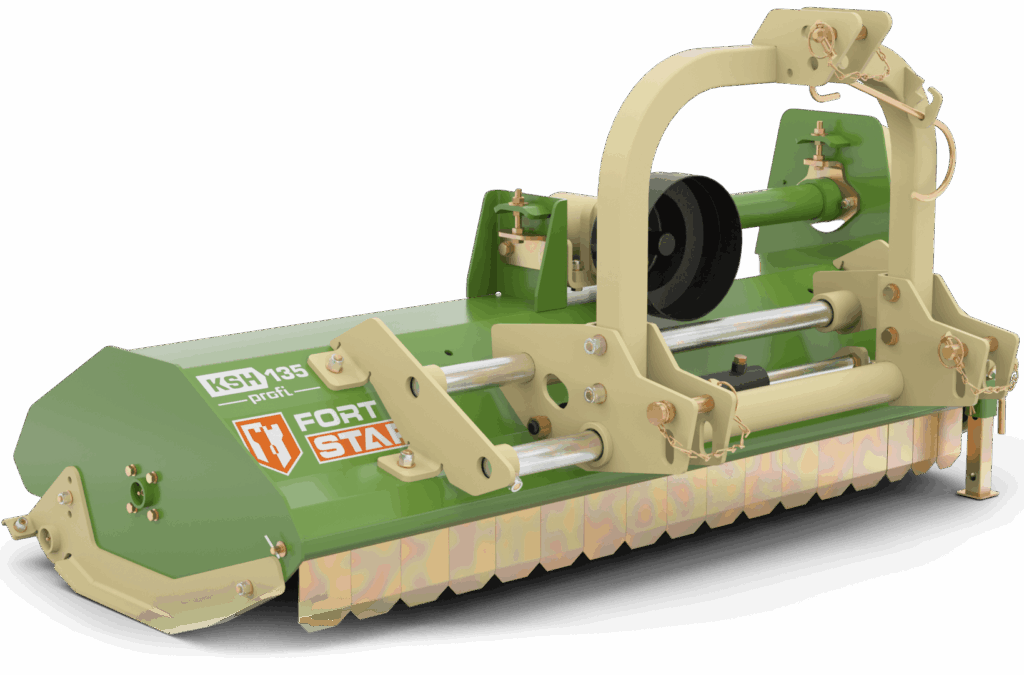

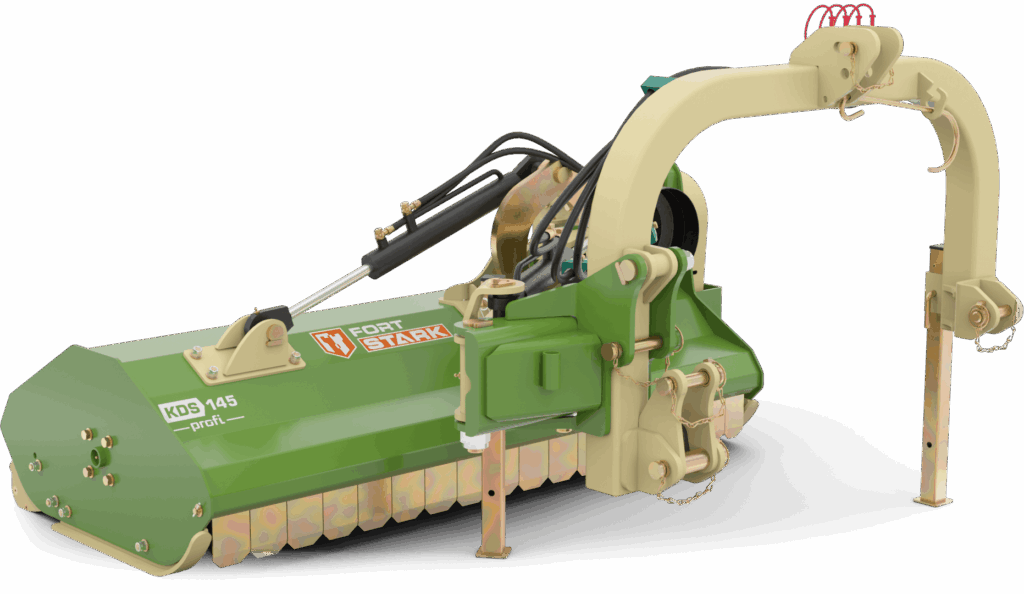

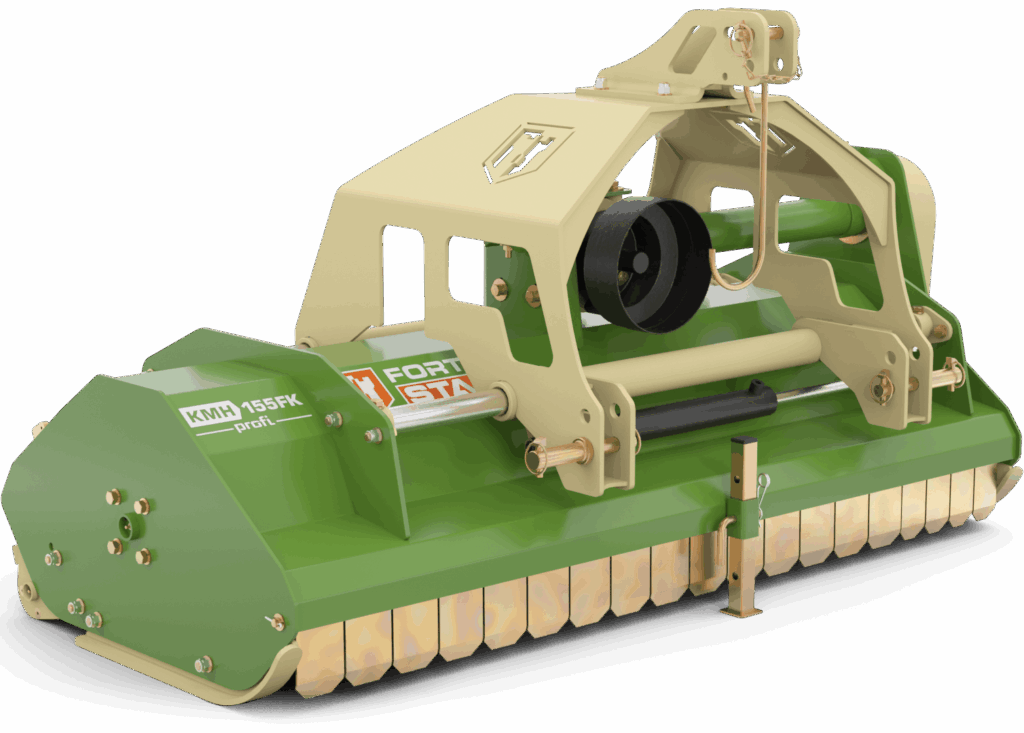

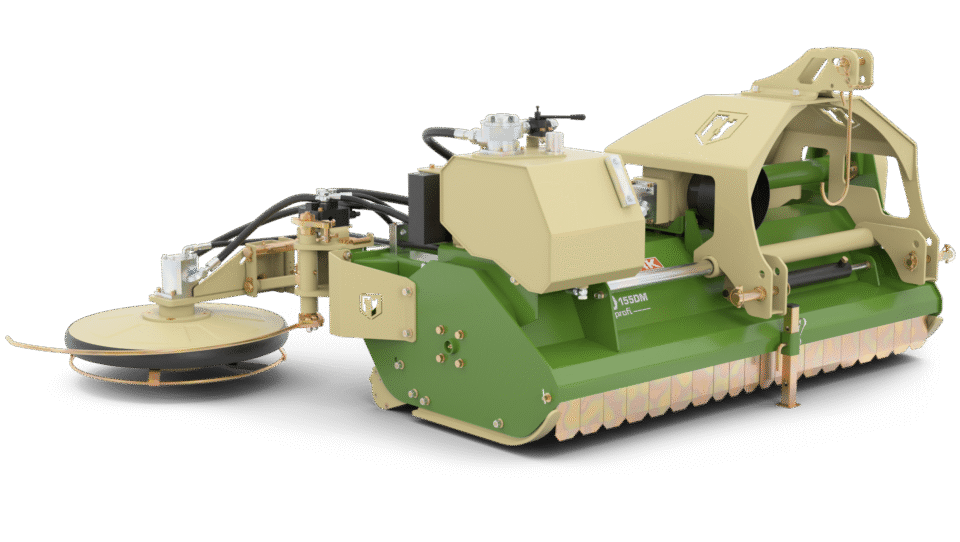

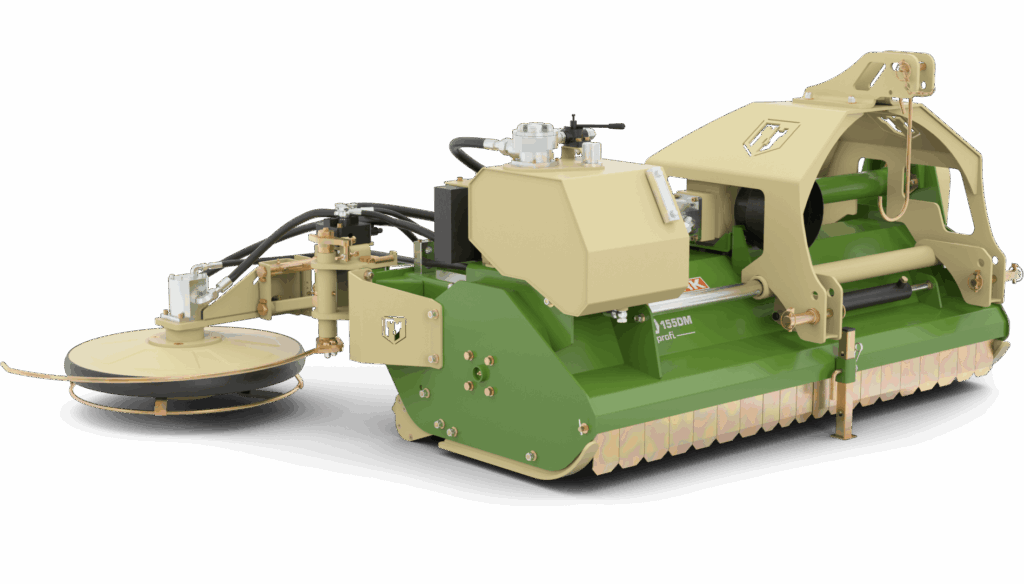

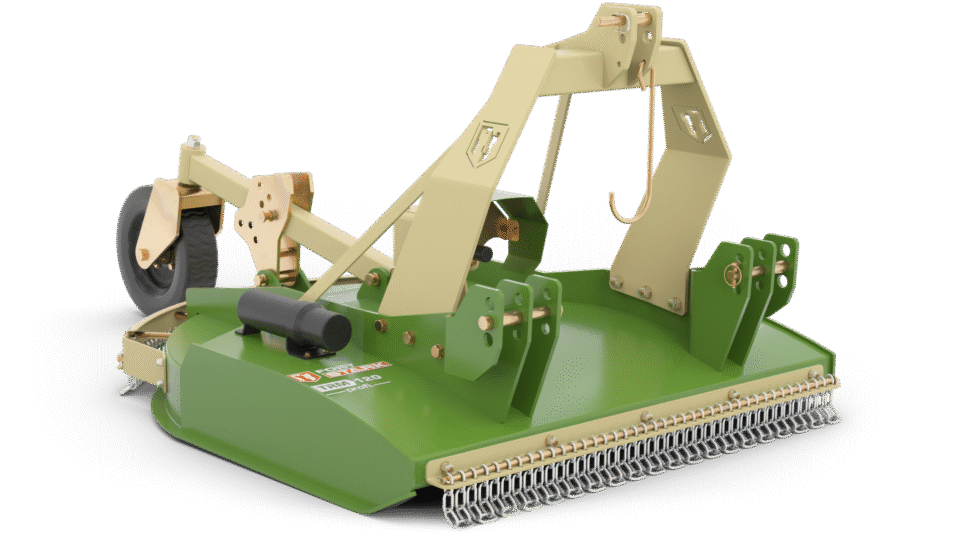

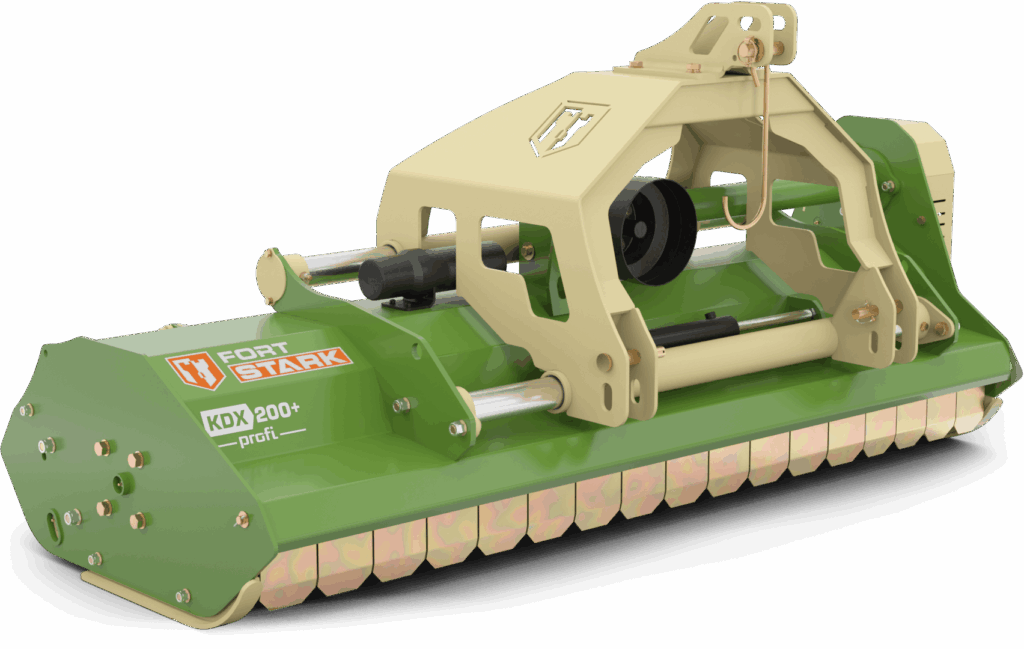

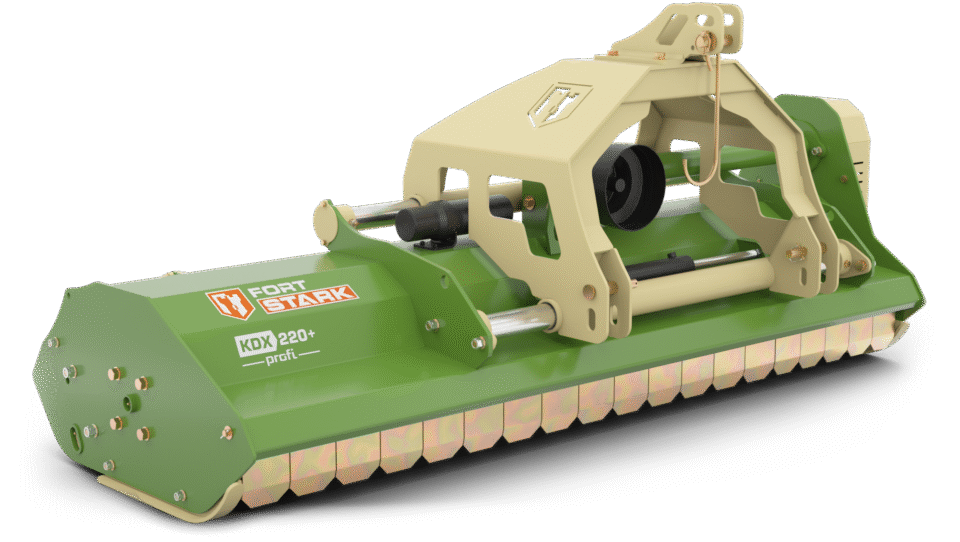

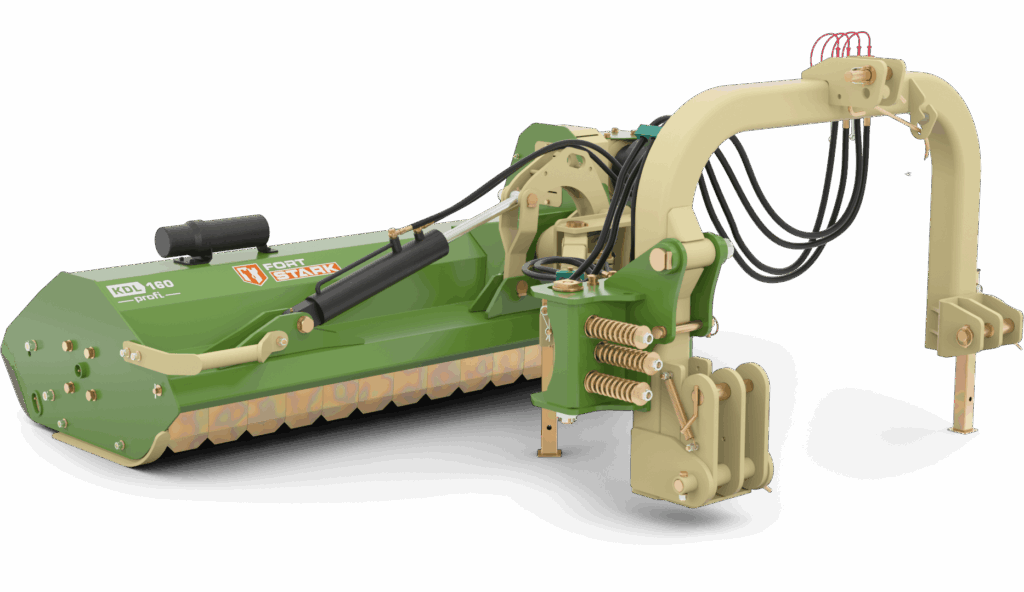

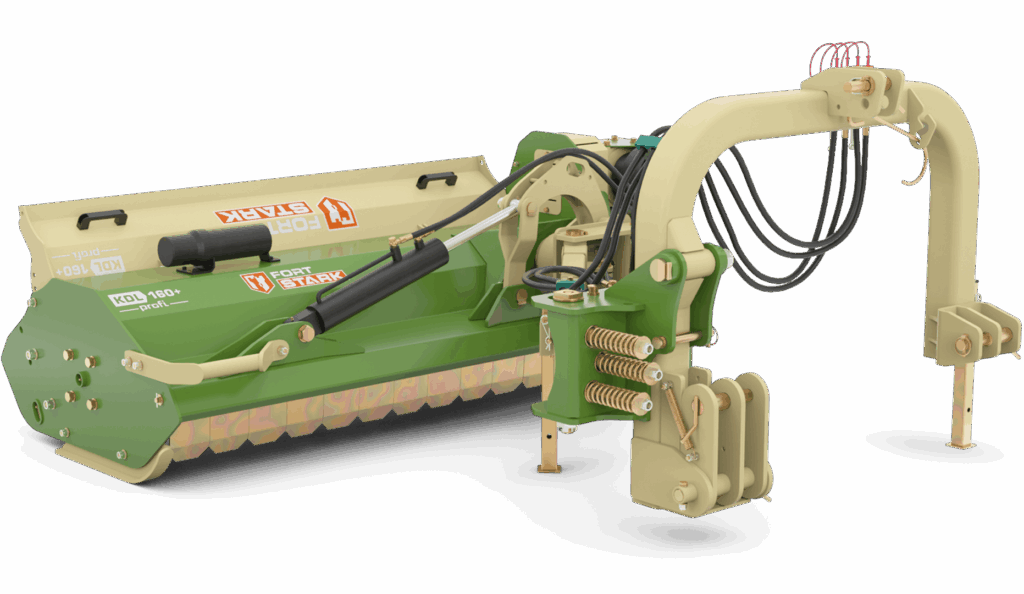

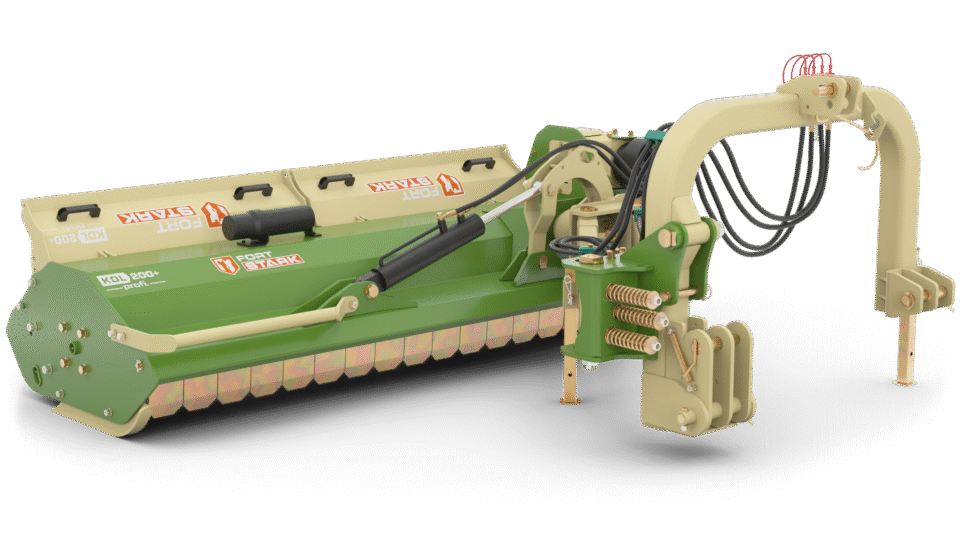

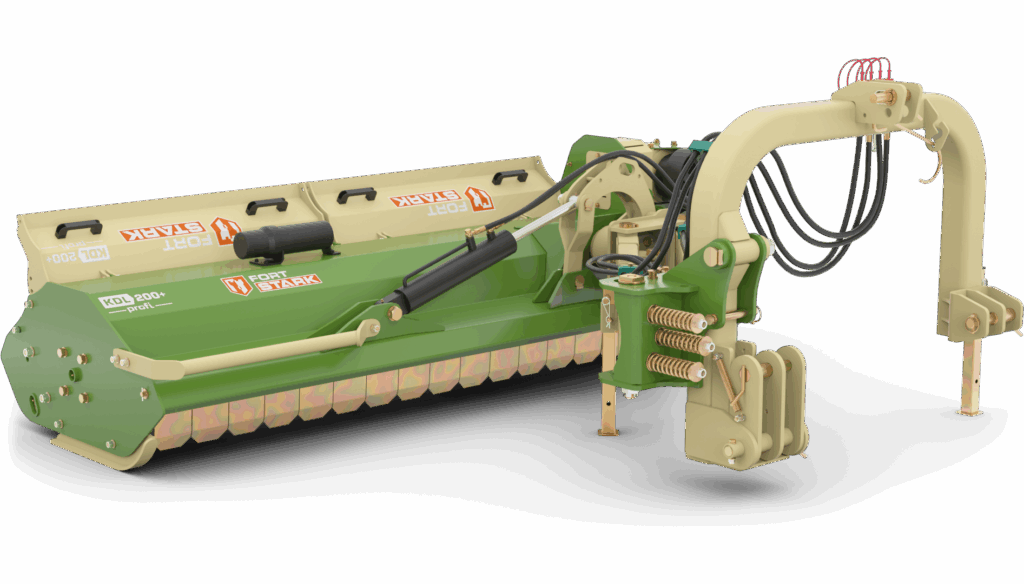

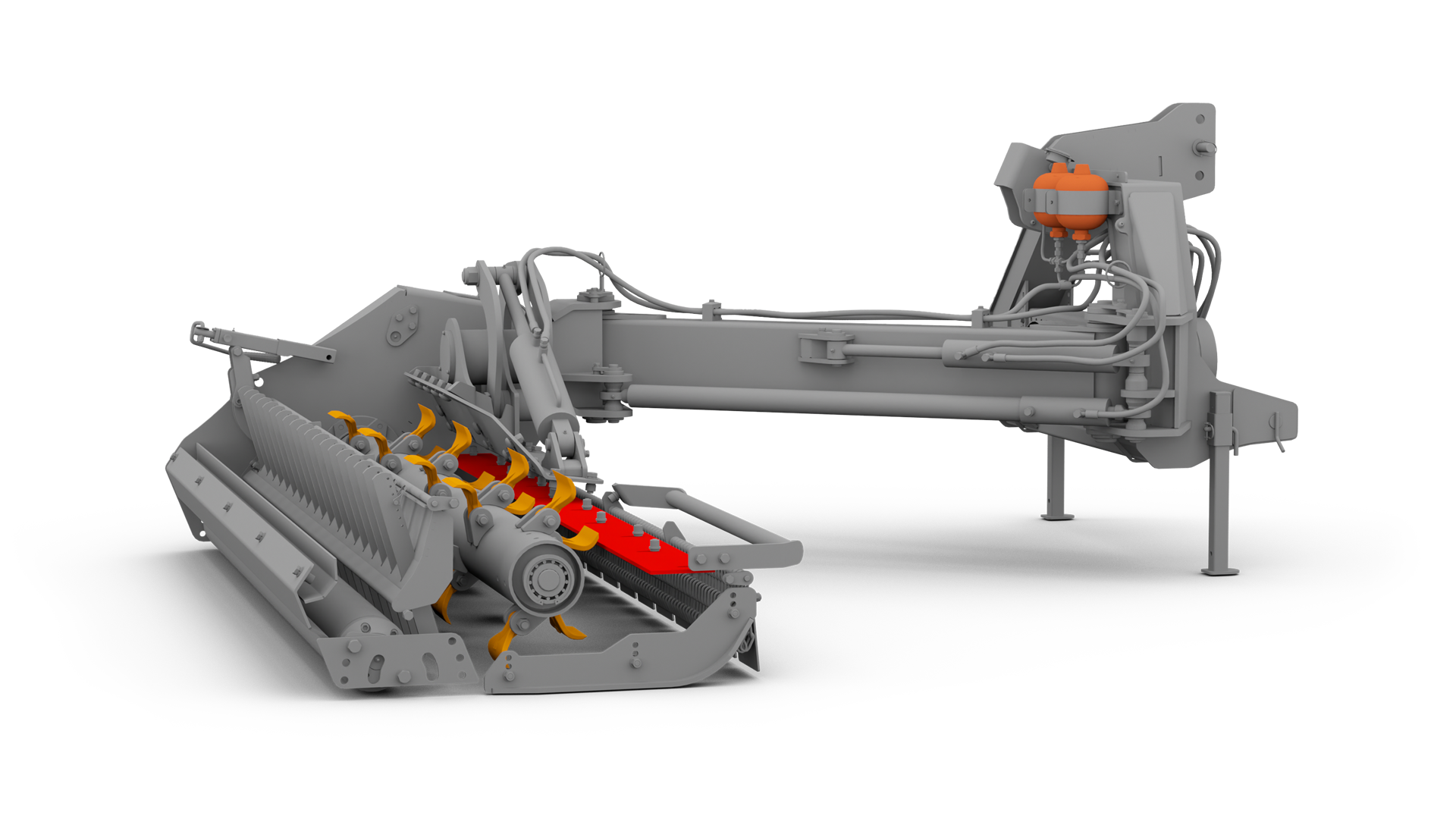

Blade-shift system cutting bar provides a precise mulching result. The smaller the clearance between the cutting bar and the rotor, the greater the suction effect. This means that even old crop residues that have previously been driven over can be processed reliably. The mulching of maize stover, for example, requires different a shredding configuration compared to the chopping of catch crops.

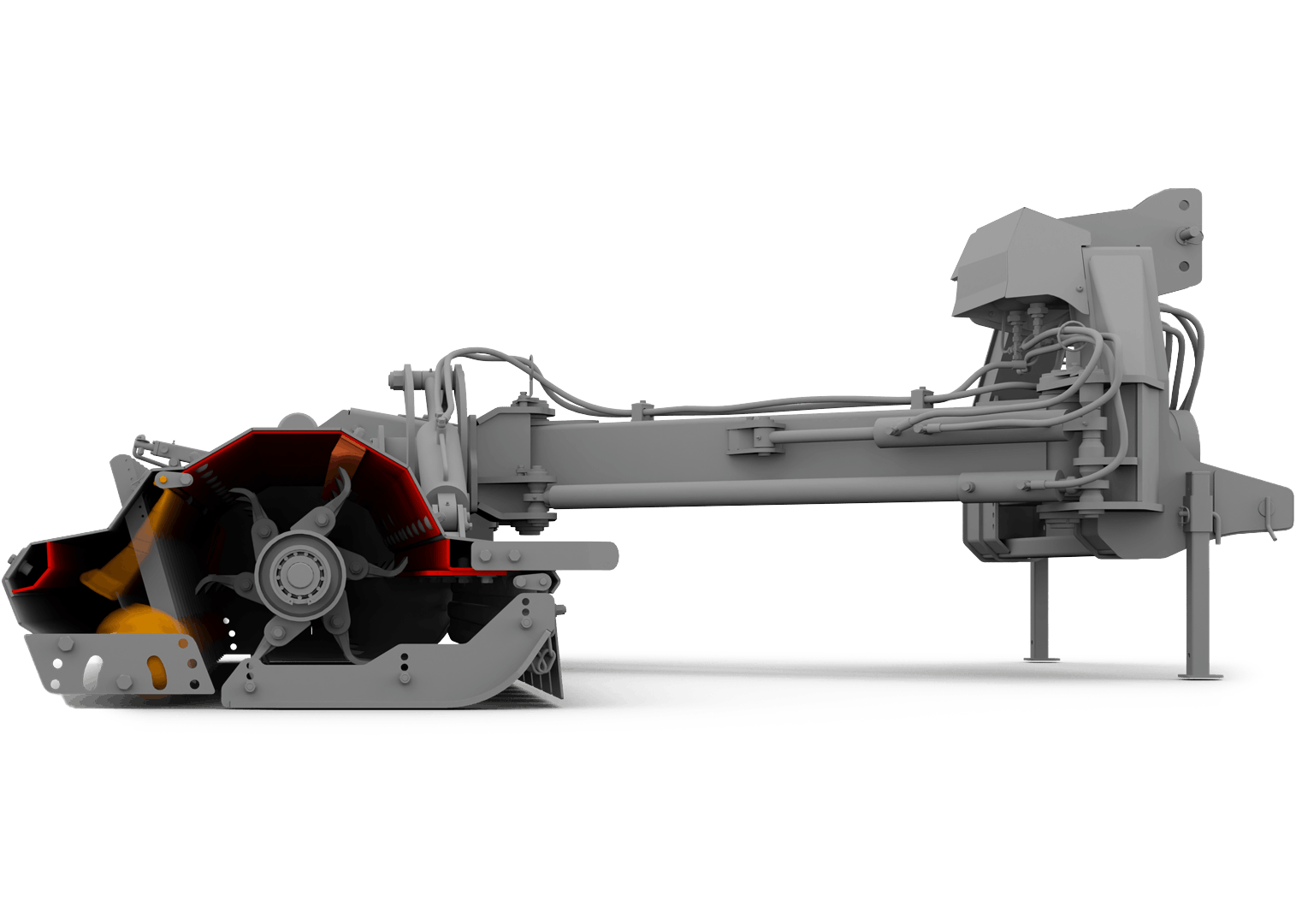

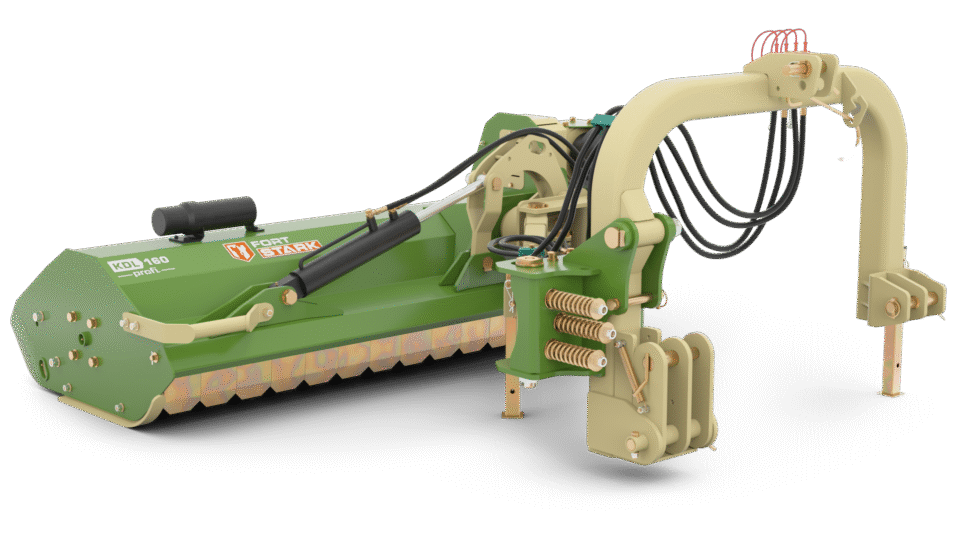

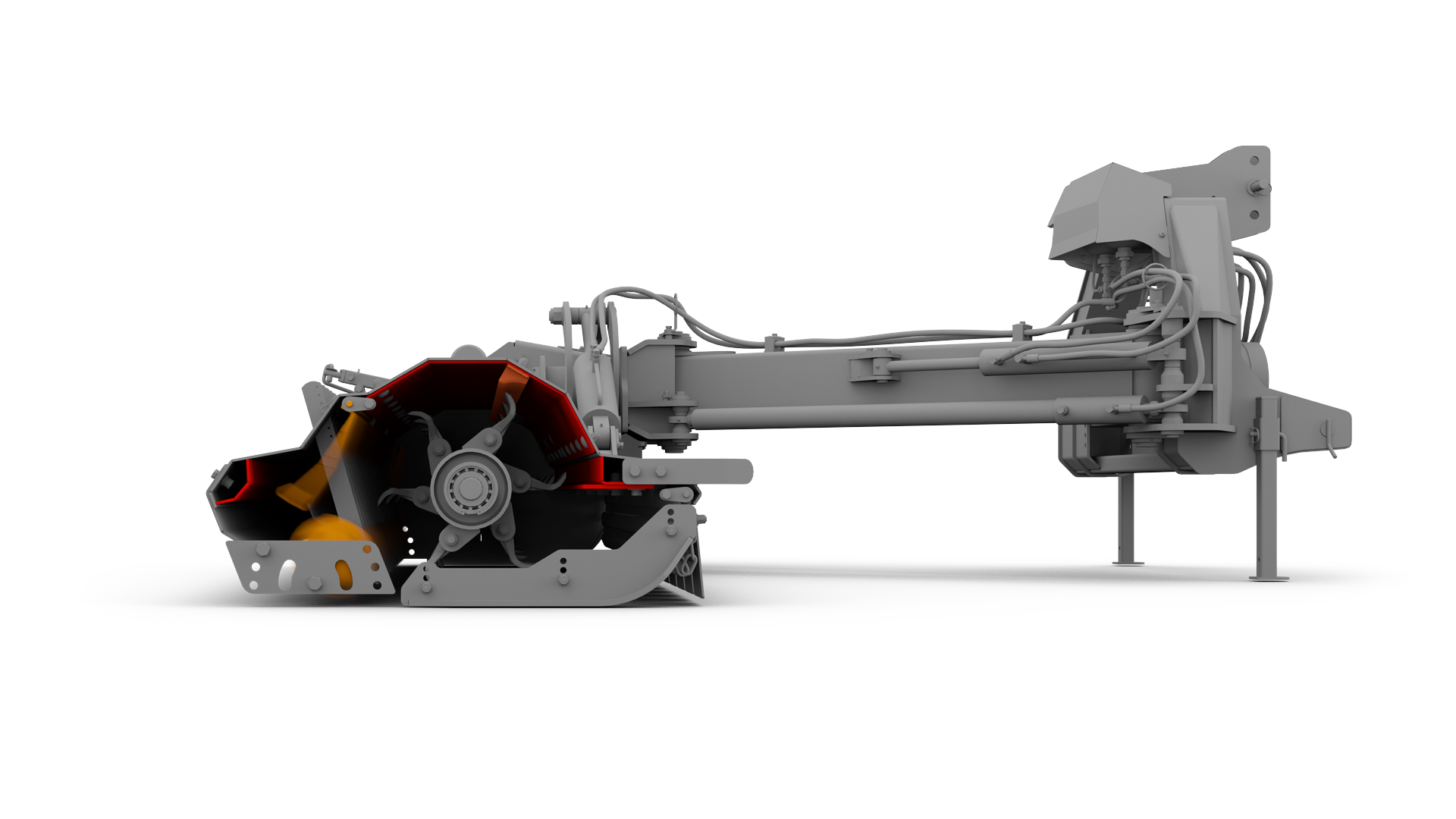

In the event of meeting an obstruction, it protects the structural parts from potential breakages and accidental damage. As the head is forced back by the obstruction, some of the oil contained in the hydraulic cylinder of the machine transfers into the nitrogen pressurized accumalator which brings the machine back to working position once the obstacle has been passed

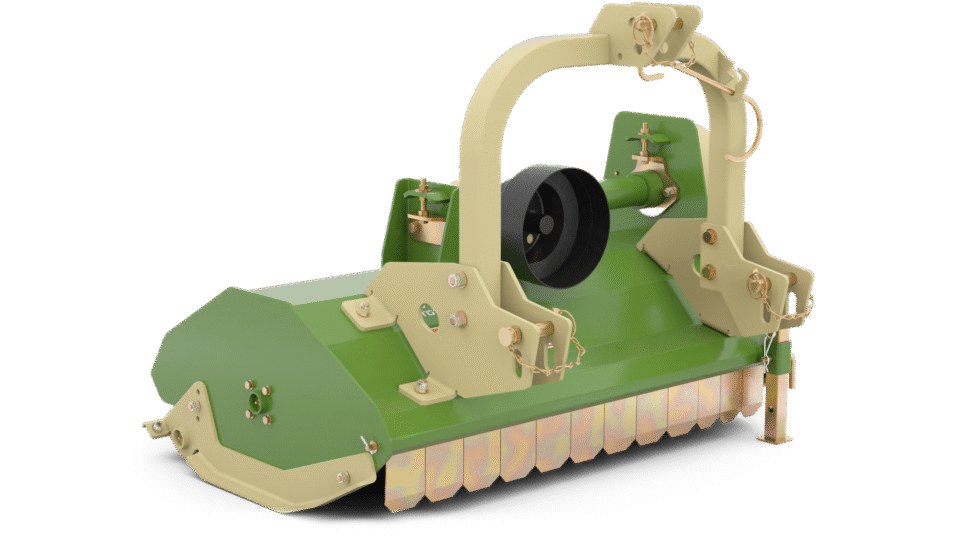

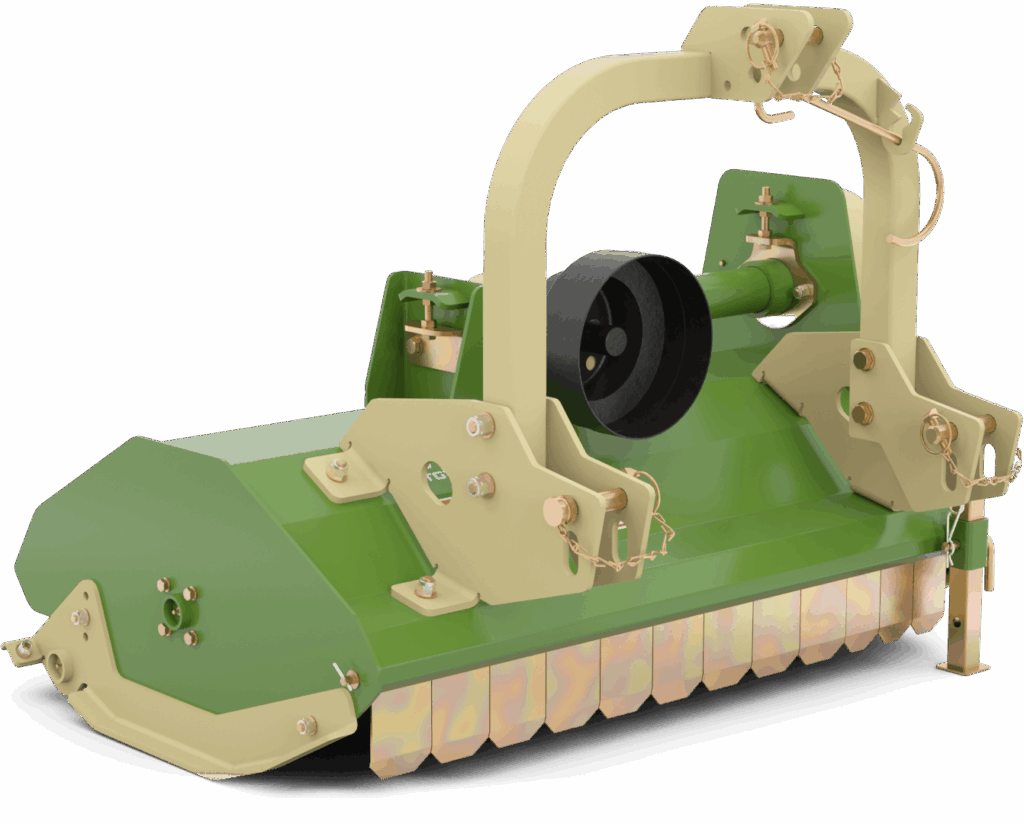

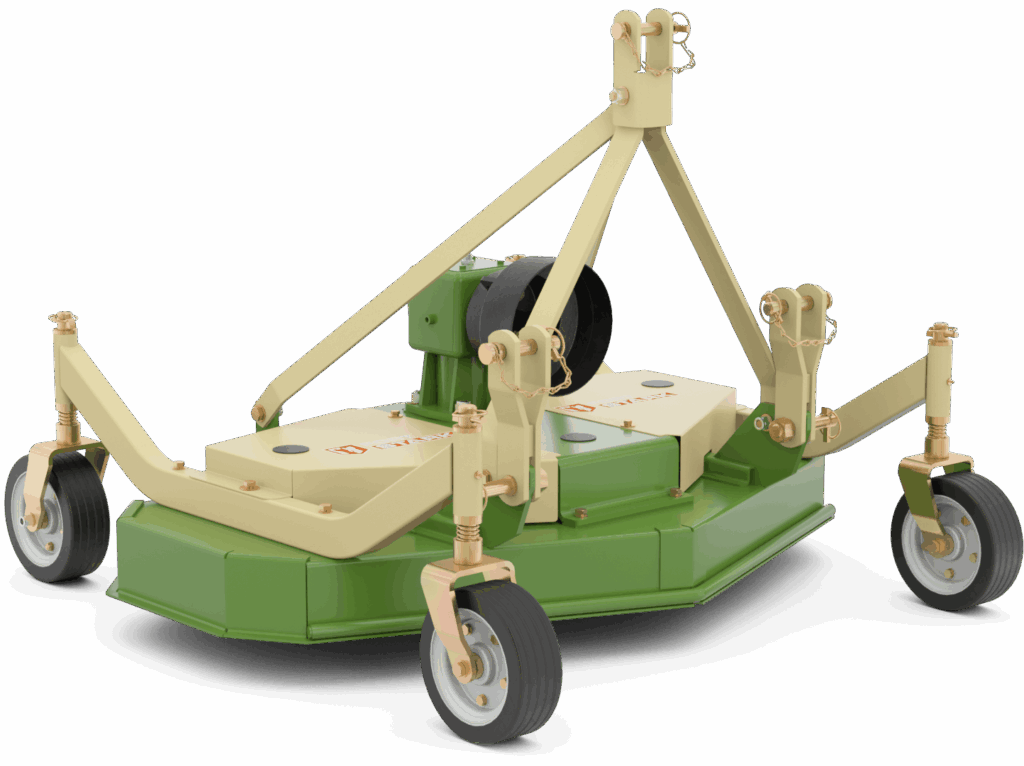

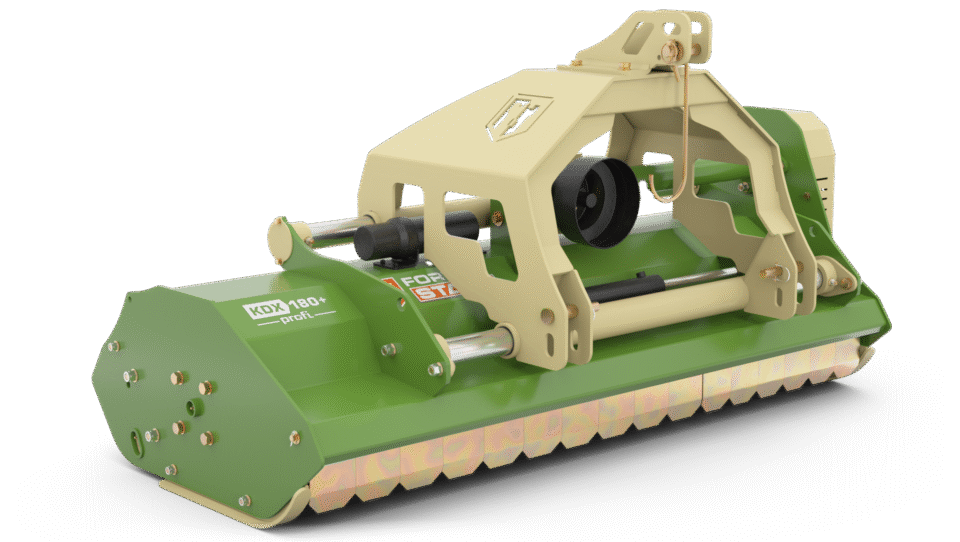

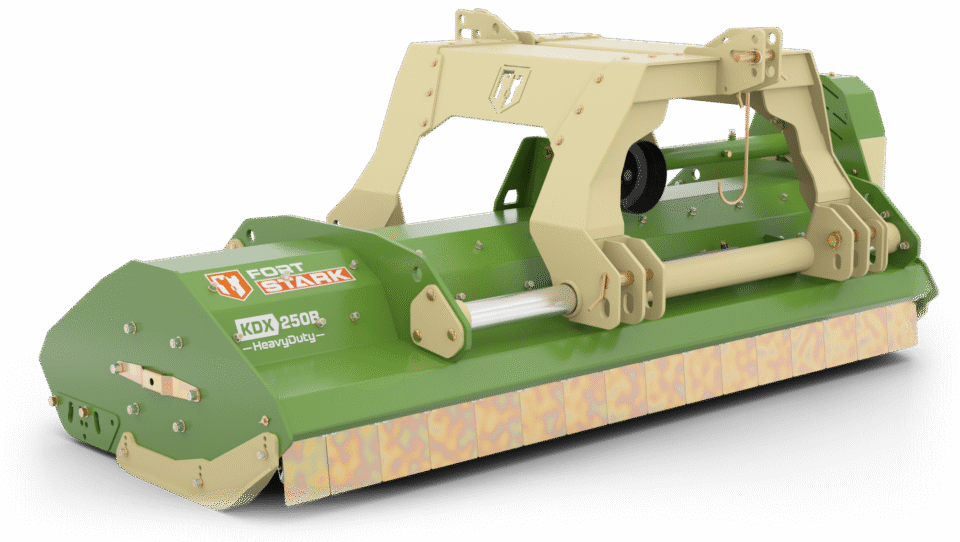

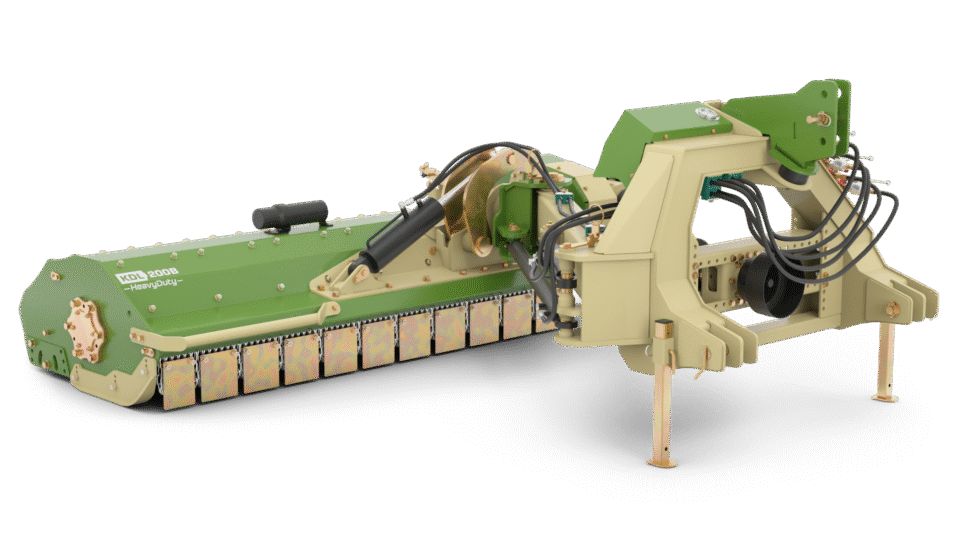

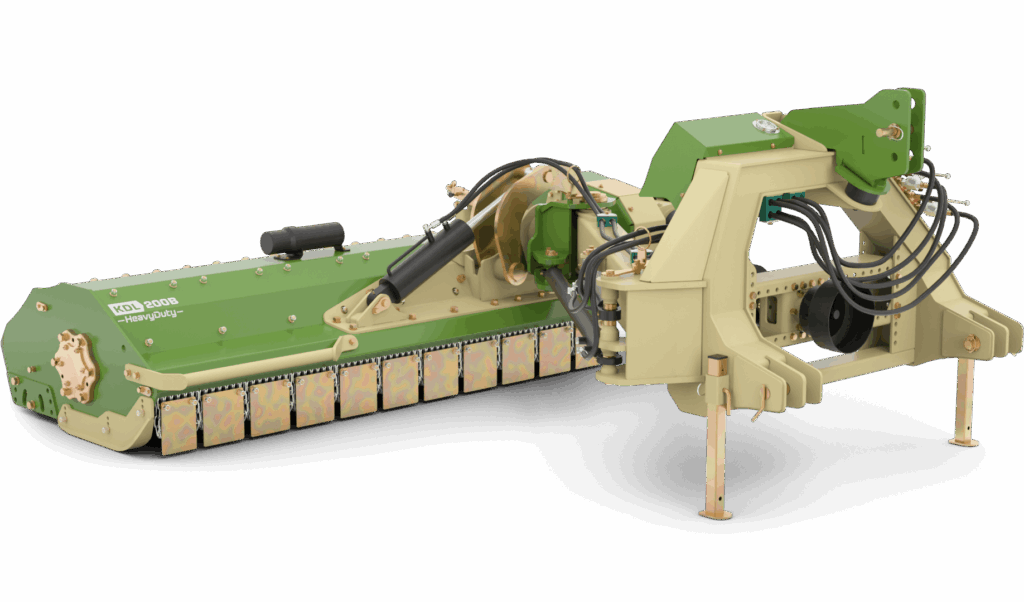

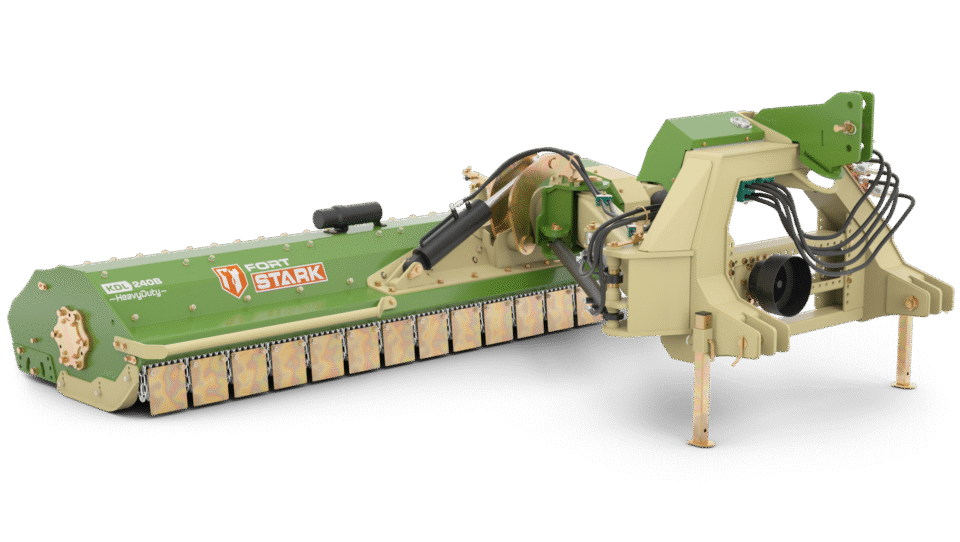

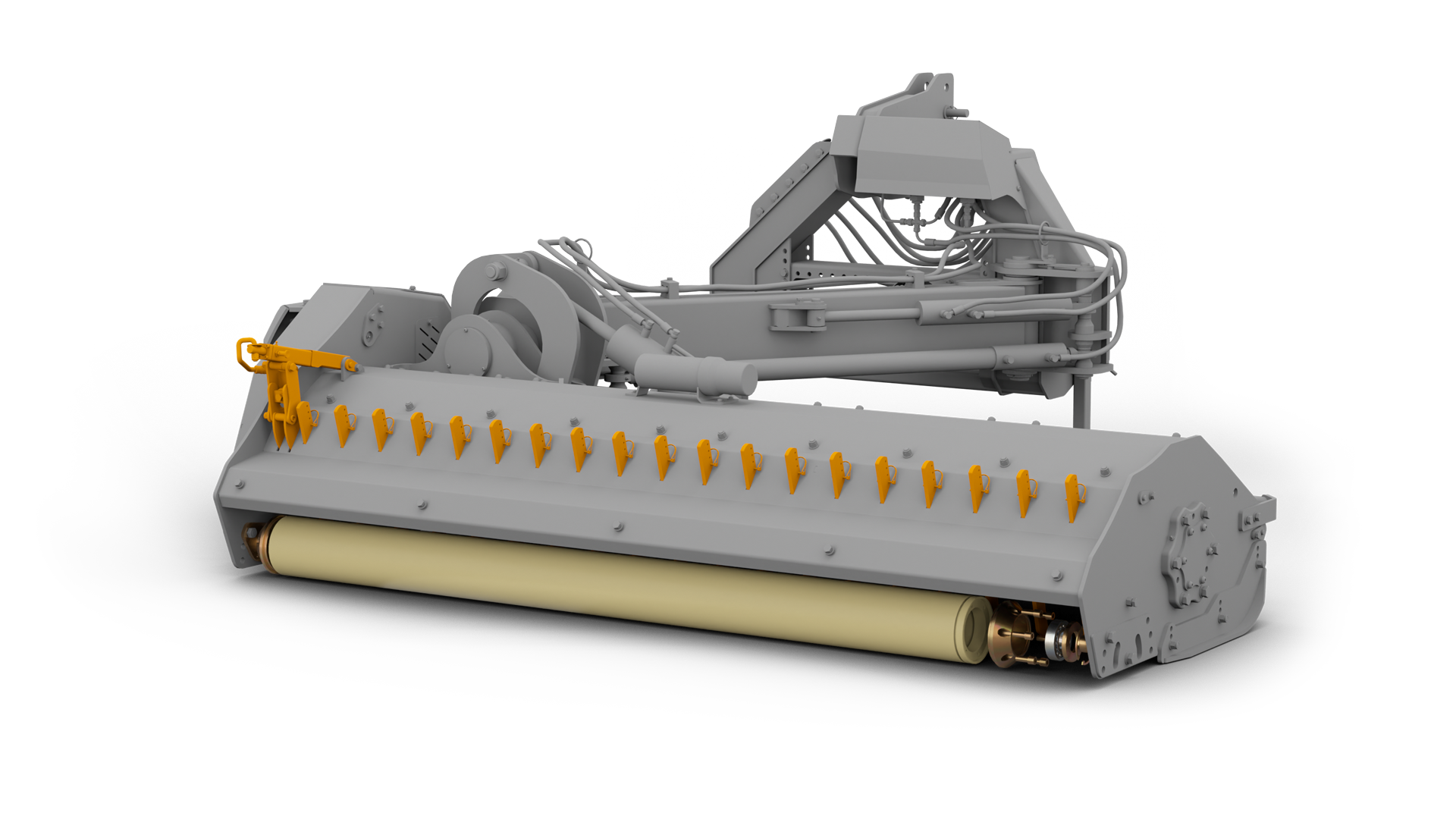

Mulching chamber KDL-B HD designed to allow for an adjustable mulching volume; by changing the position of the flow flap and pivoting rear roller it is possible to obtain two different types of work.

a) Turbo-mulcher grass mowing function: the flow flap remains up, and the mulched product is thrown out of the machine (cutting of grass, thick vegetation … )

b) Wood-mulching function: with the flow flap kept let down the wo-oden residues are finelymulched: they remain within the chamber until they are mulched as finely as possible (vines, underbrush, prunings, wood … )

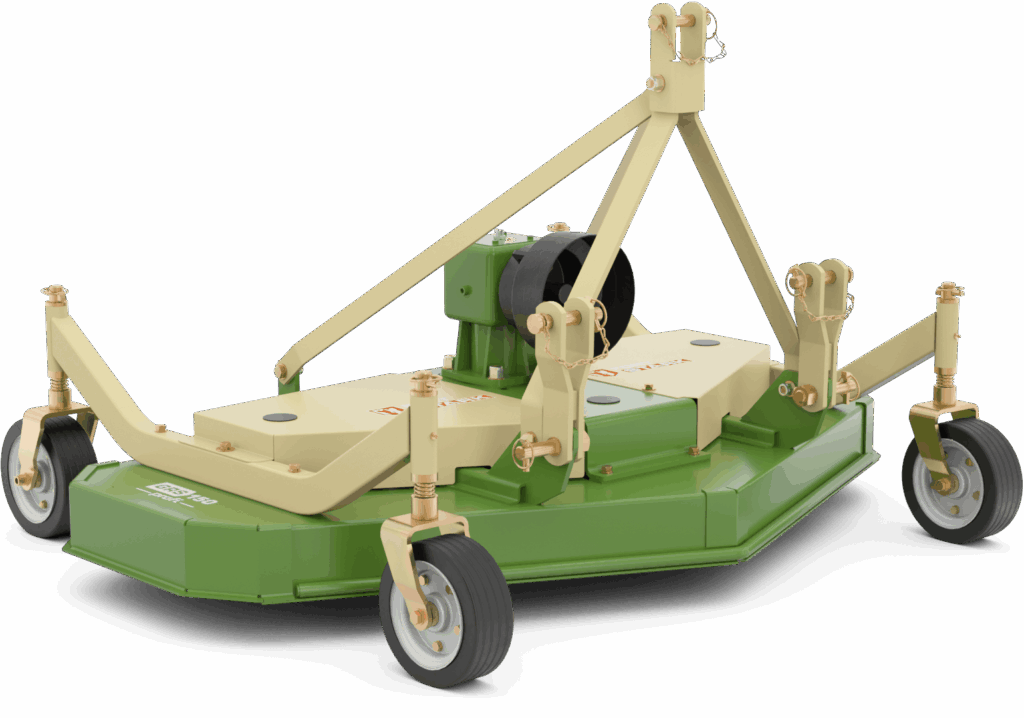

The cutting chamber on features a double-skinned construction (5 + 4 mm) The toothed counter blades allow the machine to mulch even the more voluminous residues and thicker branches into fine pieces. The body is reinforced with the addition of a sheet metal internal housing for extra strength.

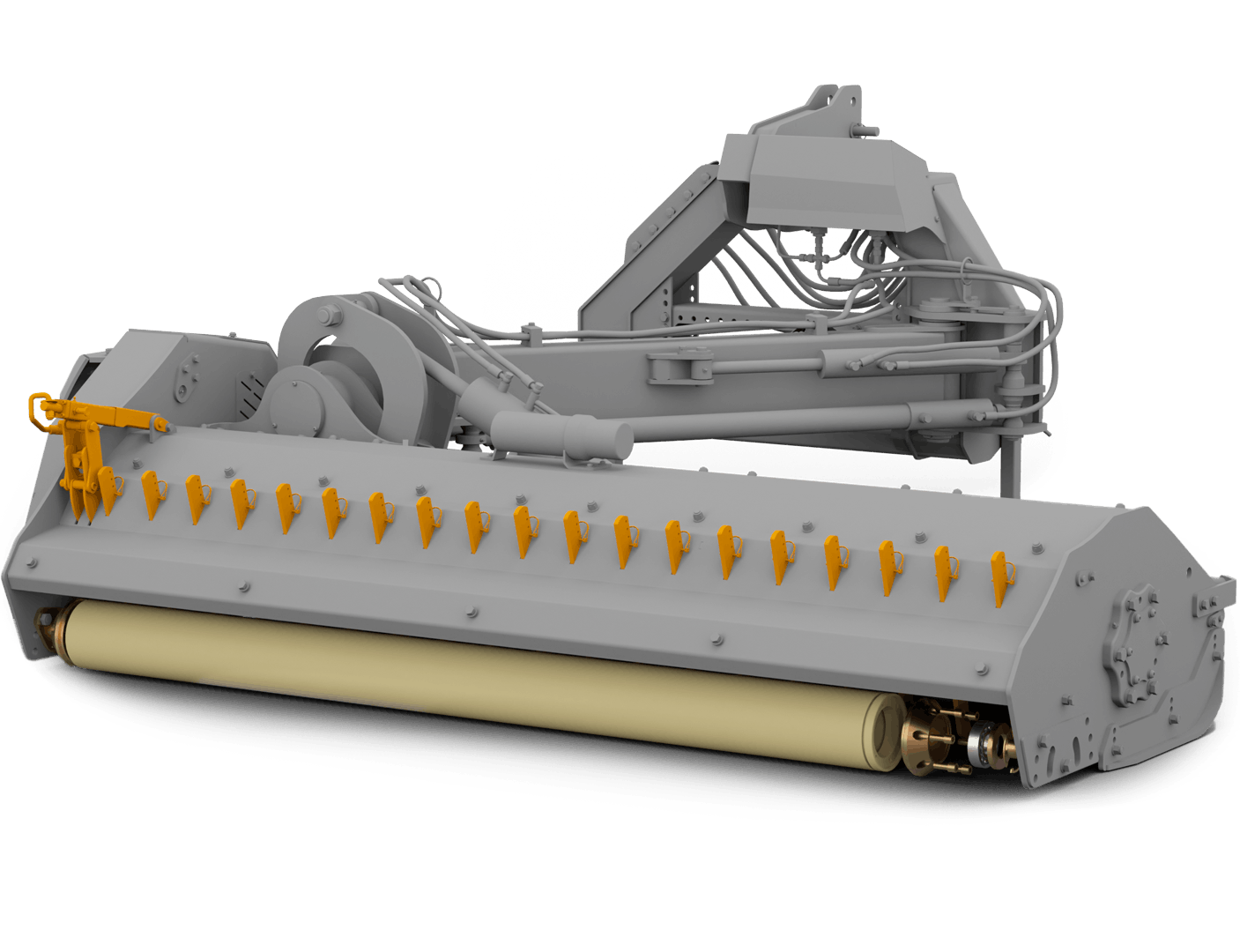

The knives has a self-cleaning and exchangeable design. It ensures uniform shredding of all of the material. Long material is fed through the rotor in a second step in the crop flow, whereas material that is already shredded passes through. The result is a homogeneous mulch.

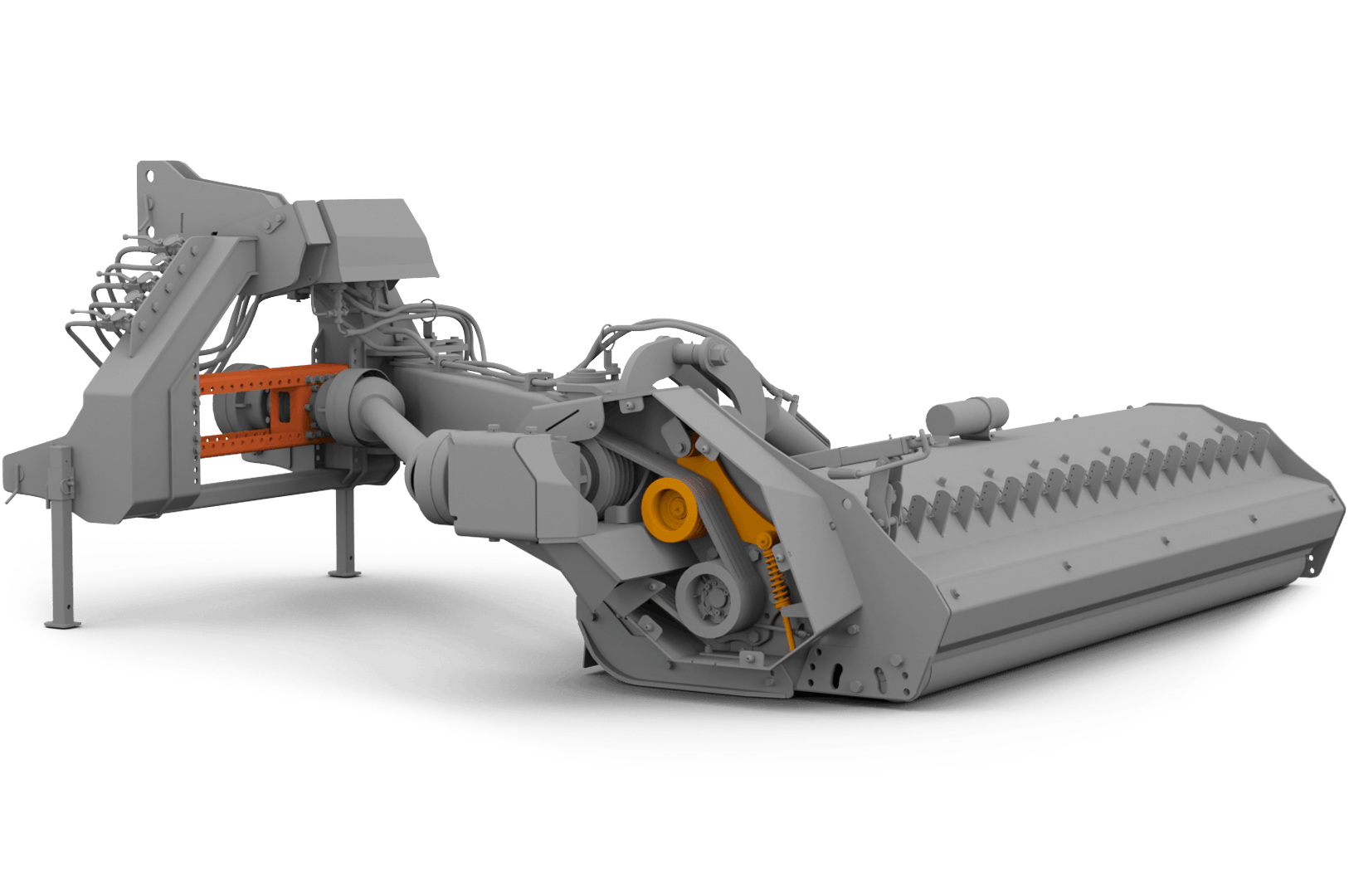

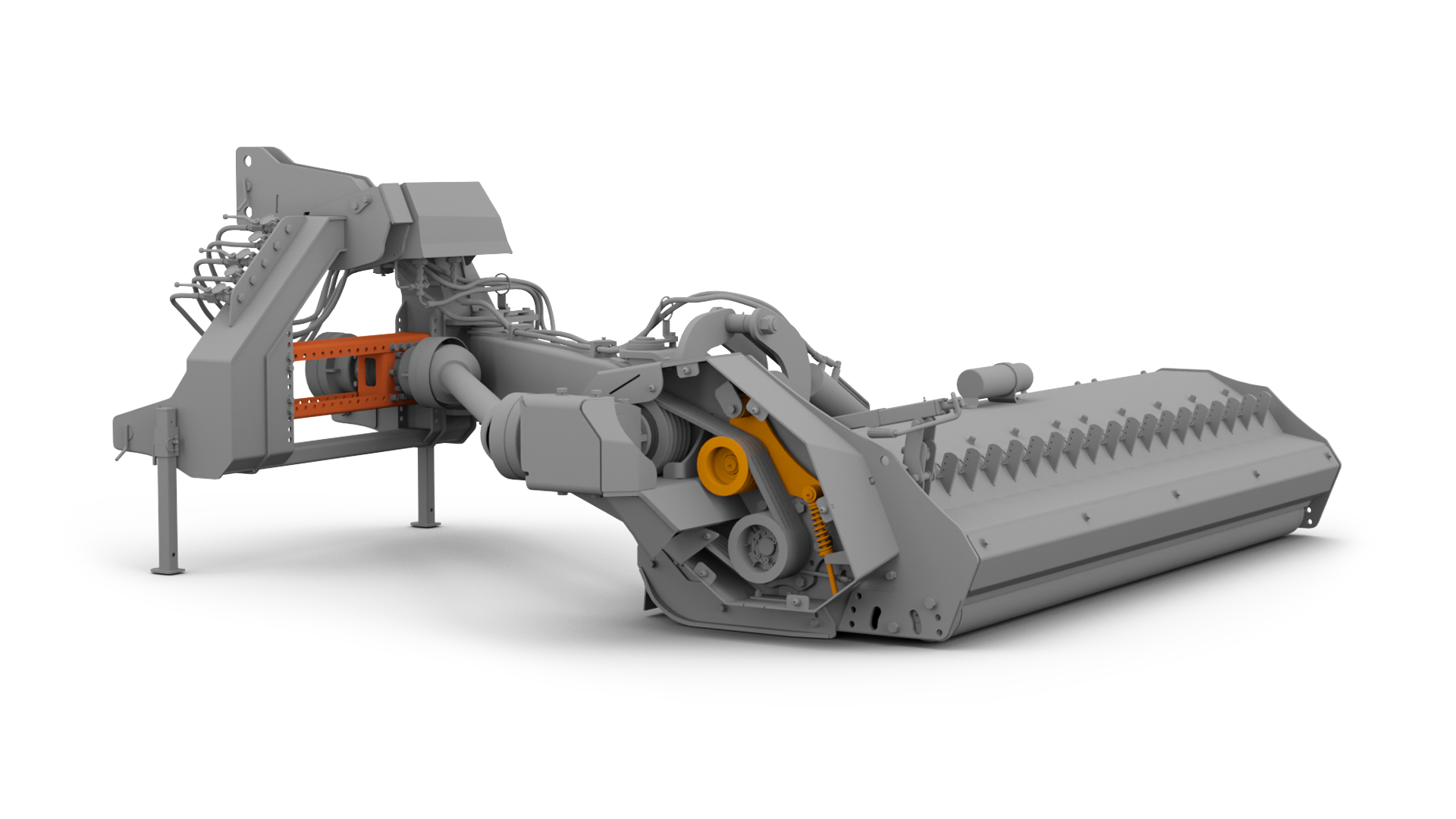

Optimal power flow due to swing drive system

Automatic belt tensioning keeps the drive belt under tension, whether it is cold or warm and whether the belt is new or already run in. Once adjusted, the tension is automatically maintained at the set level.

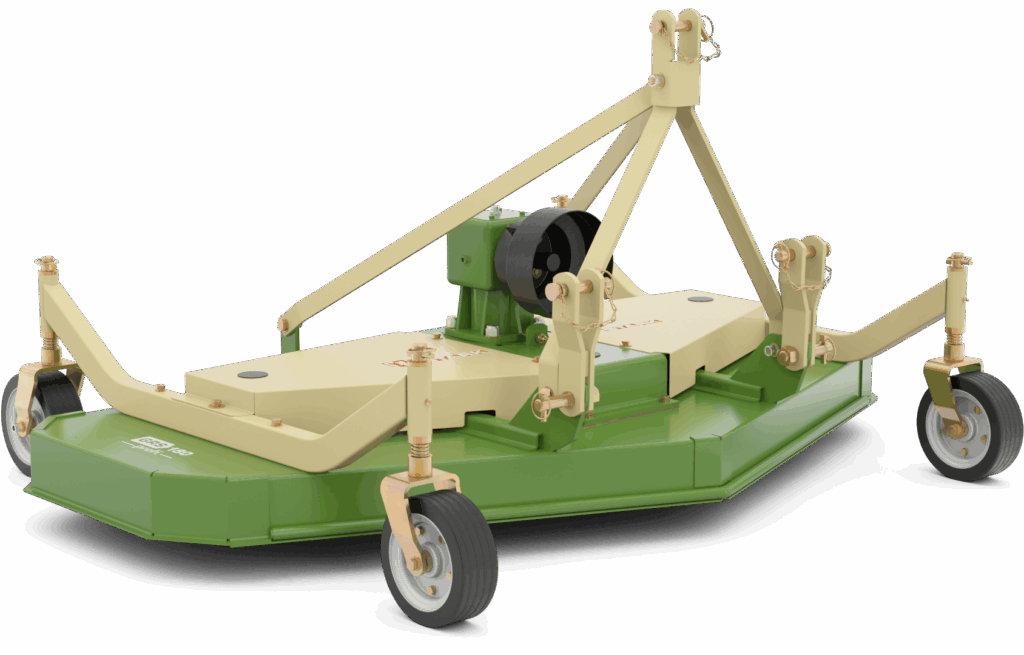

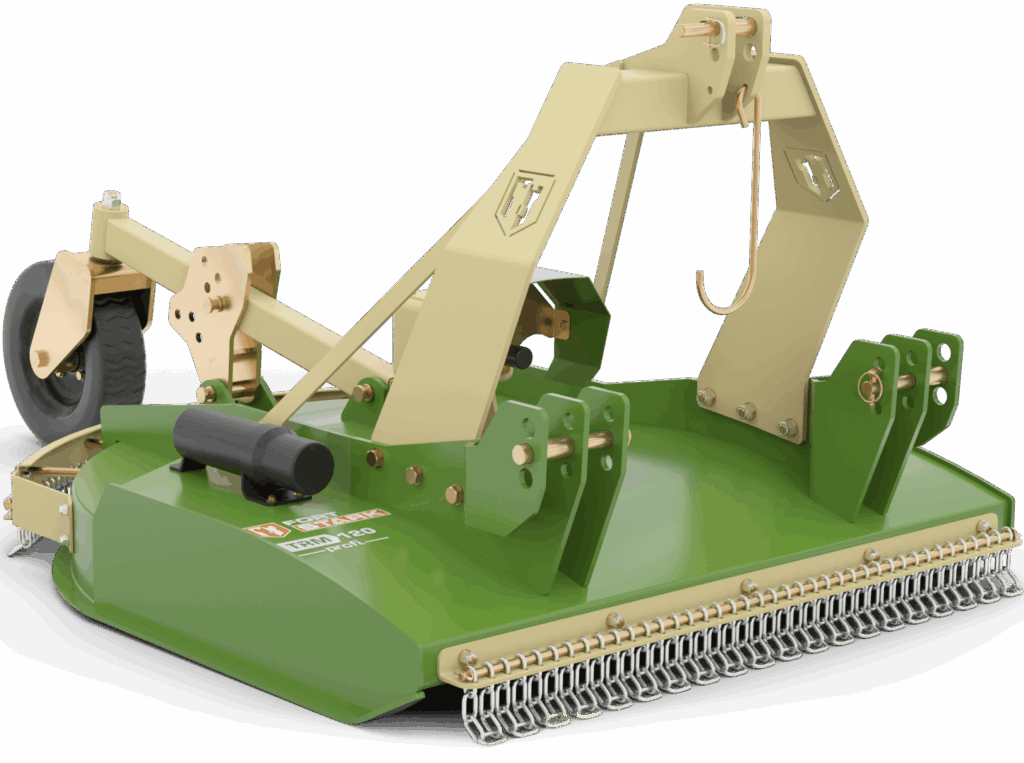

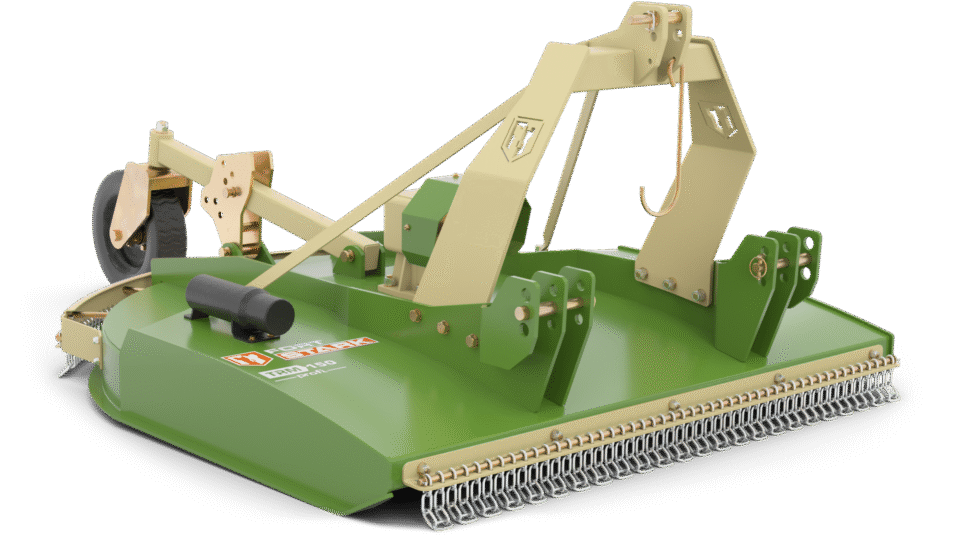

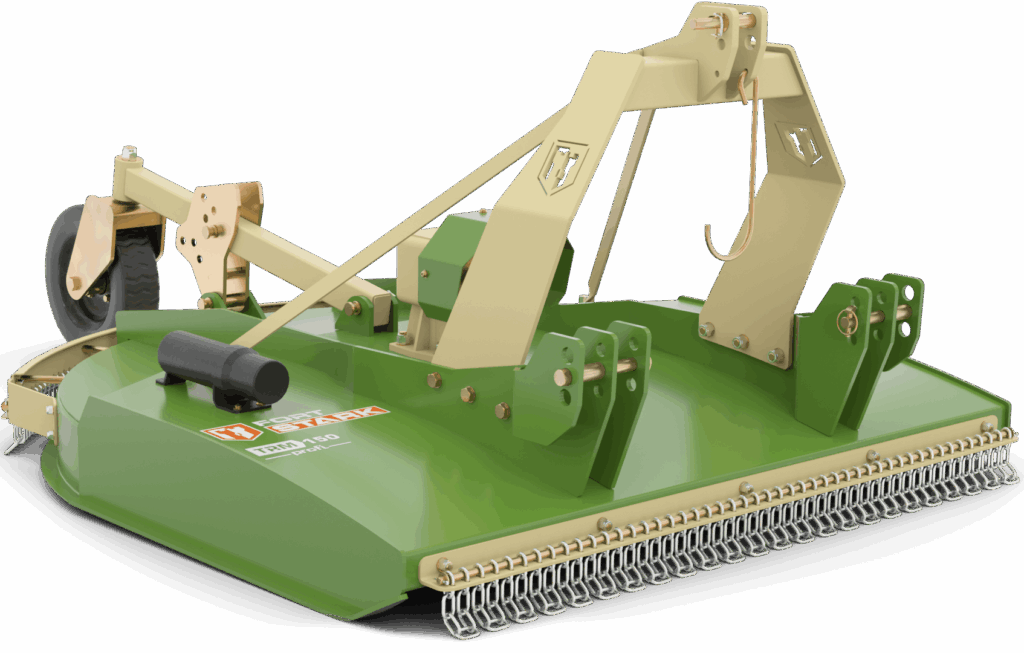

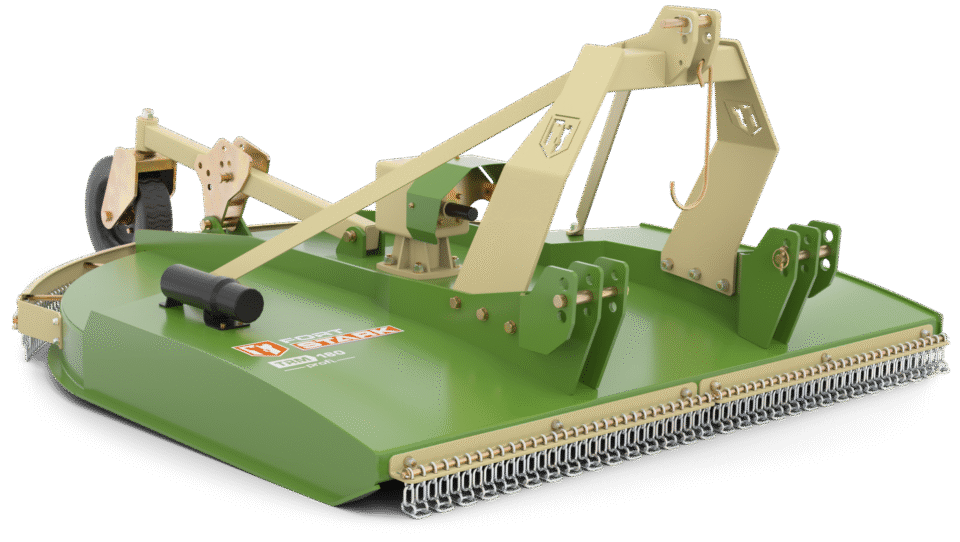

For finer mulching of the residue, KDLB-HD Profi equipped with adjustable collecting rakes. Residue is retained under the bonnet, allowing it to be broken down further to a given size.

Roller of 150 mm with removable ends

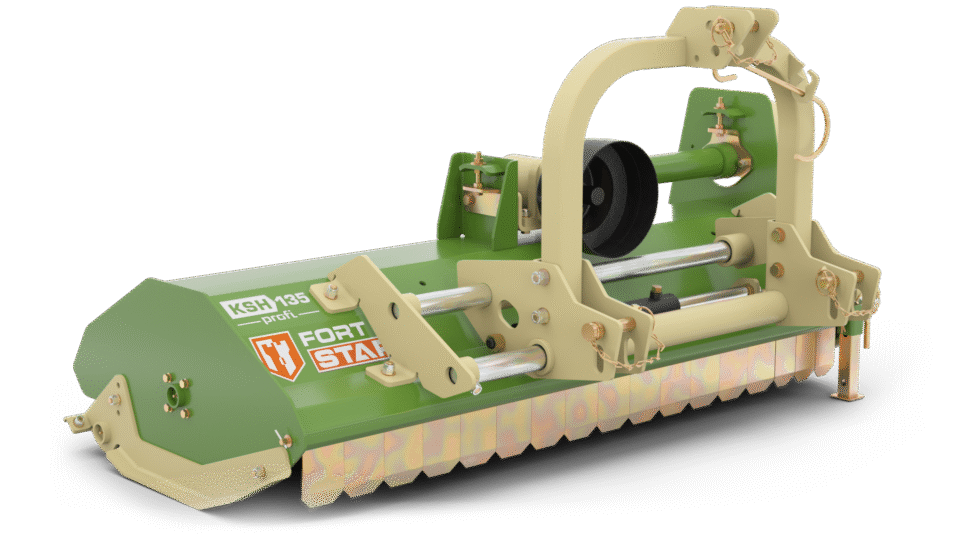

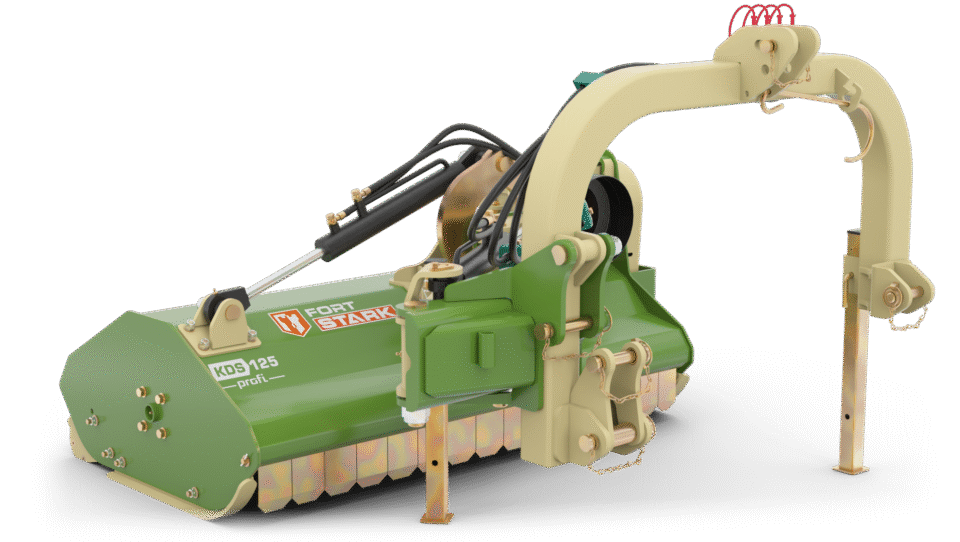

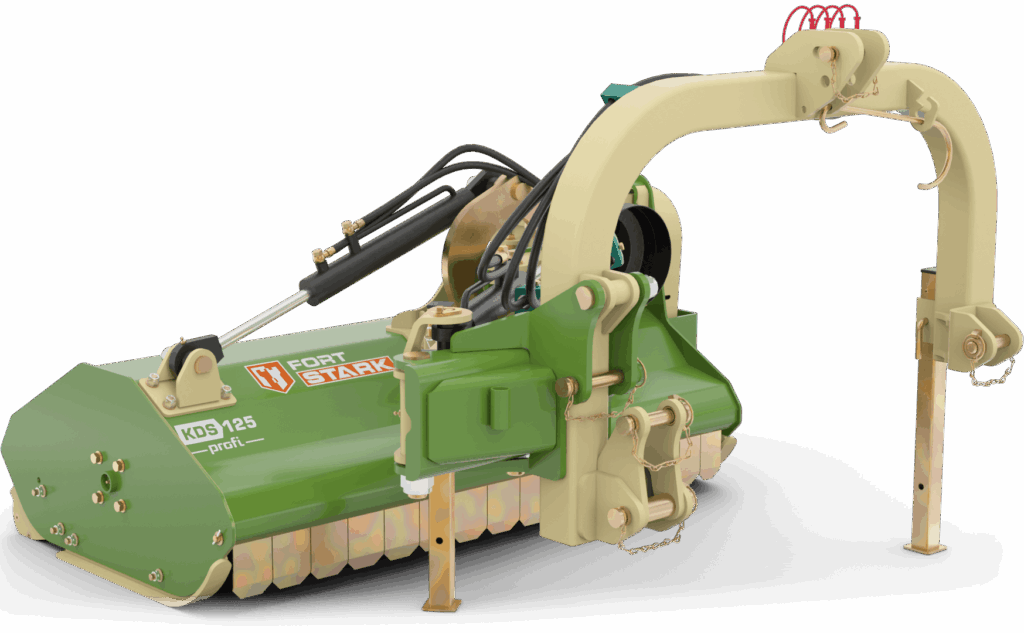

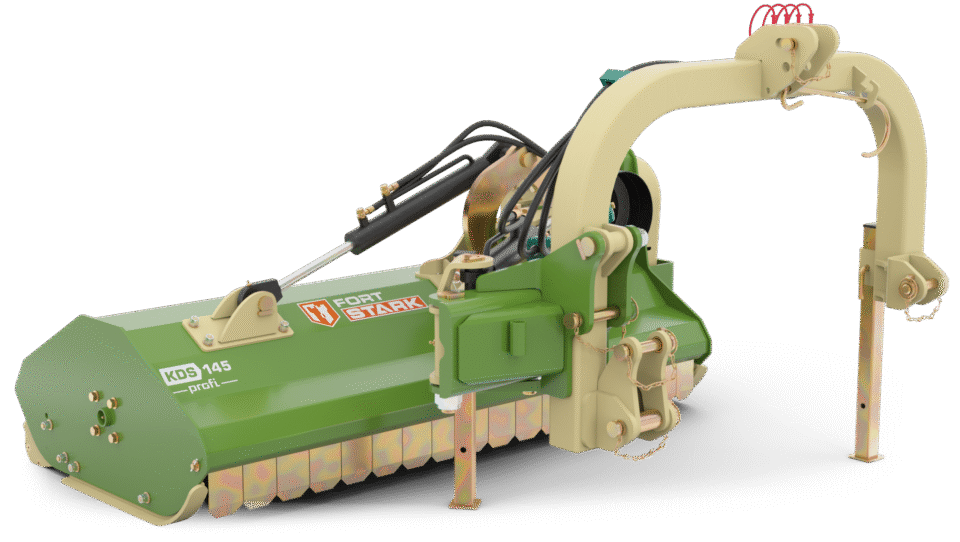

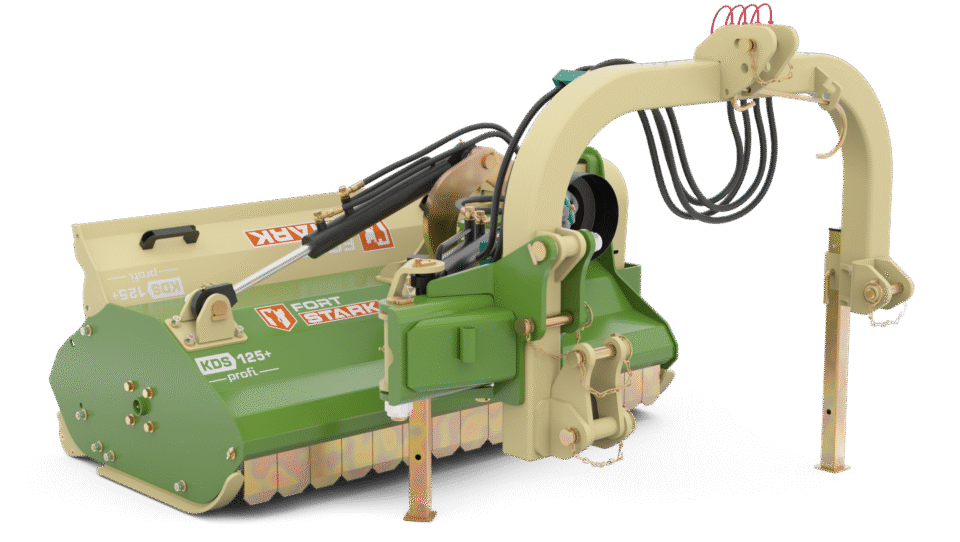

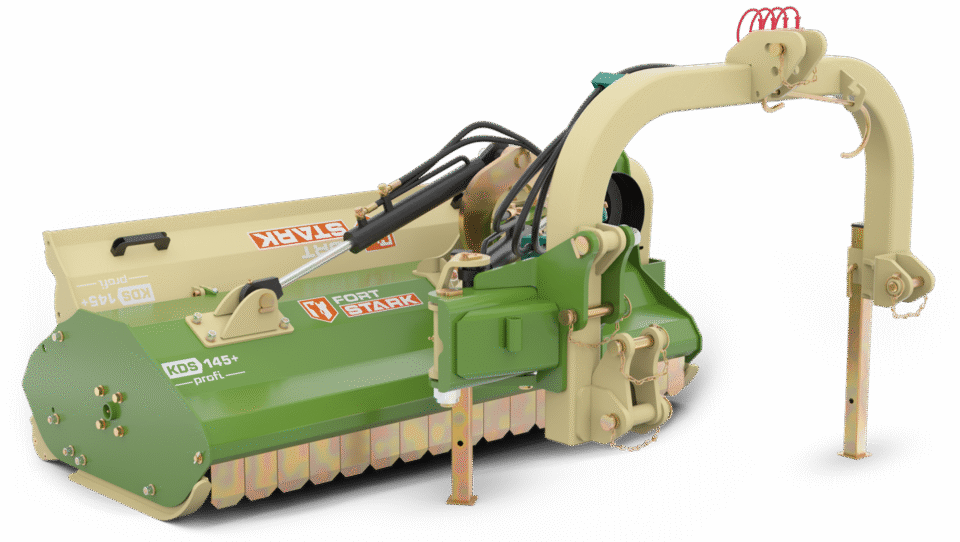

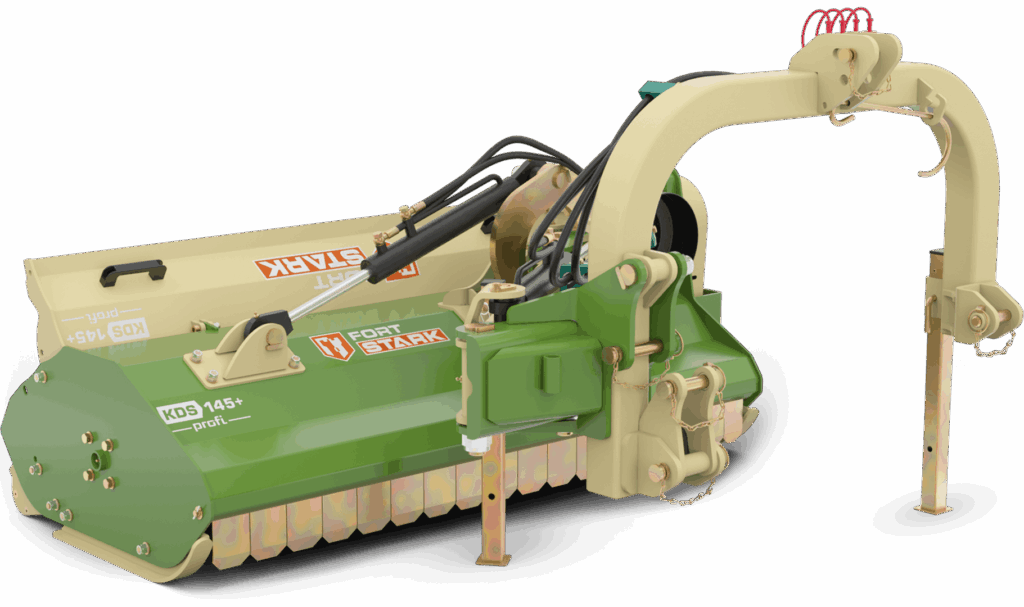

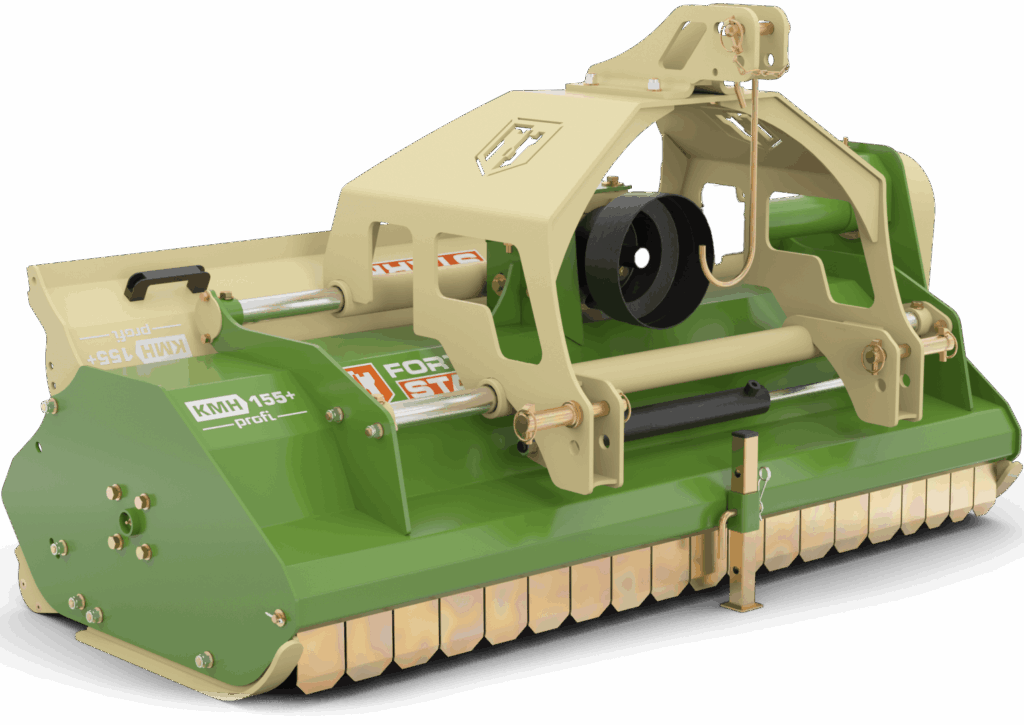

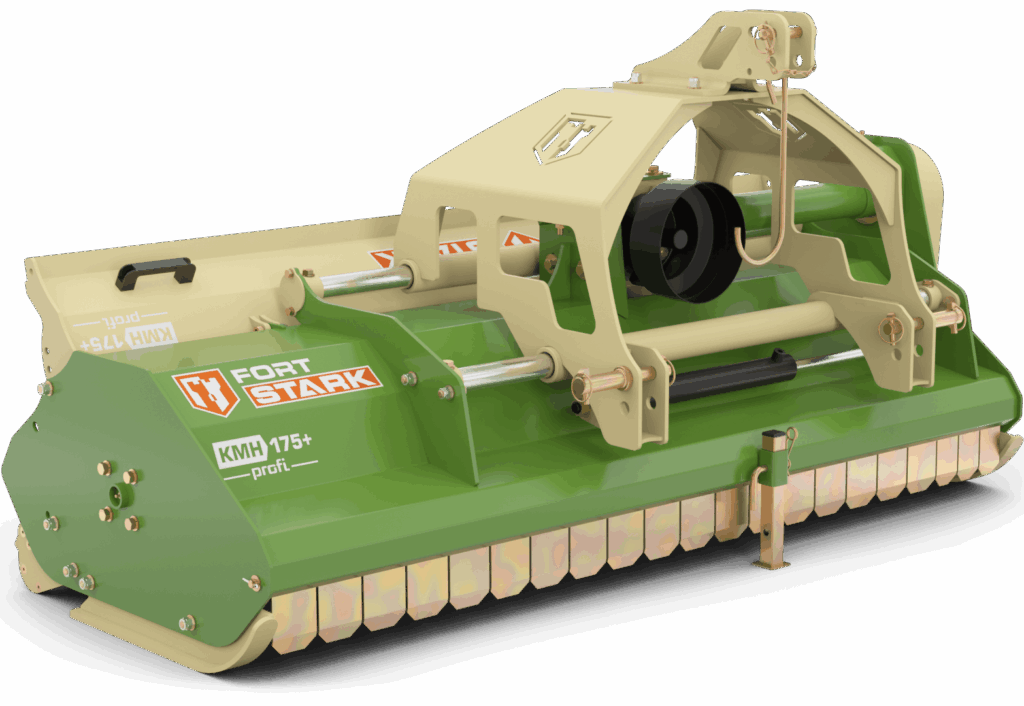

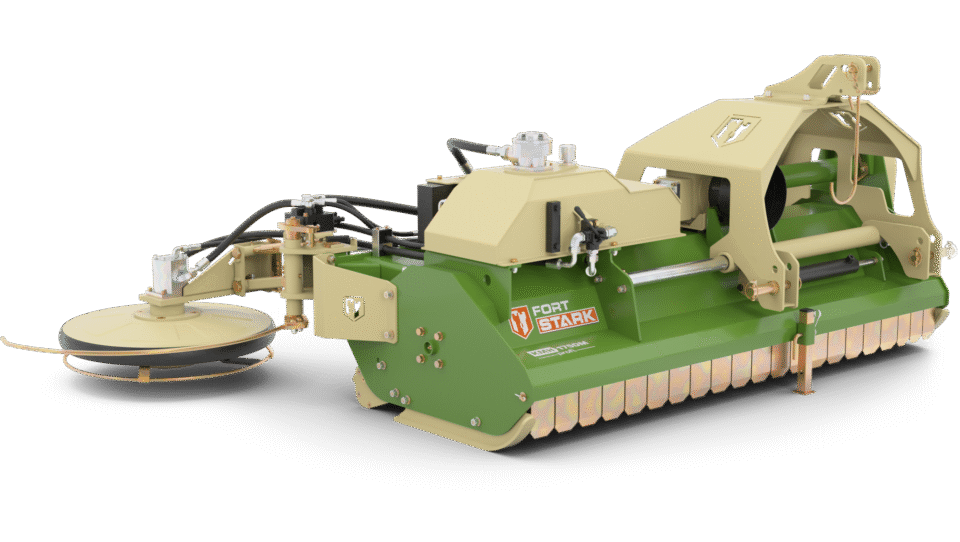

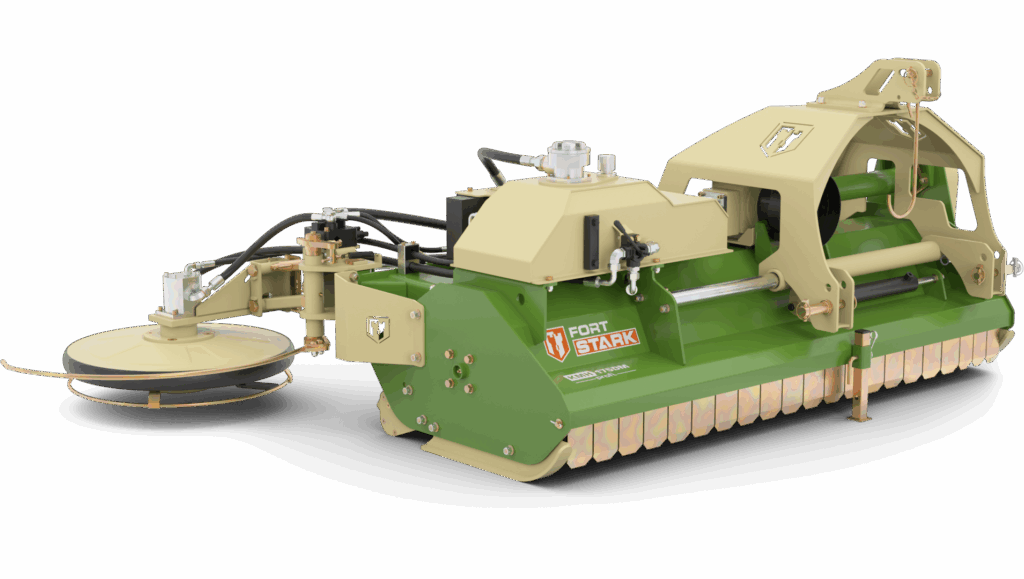

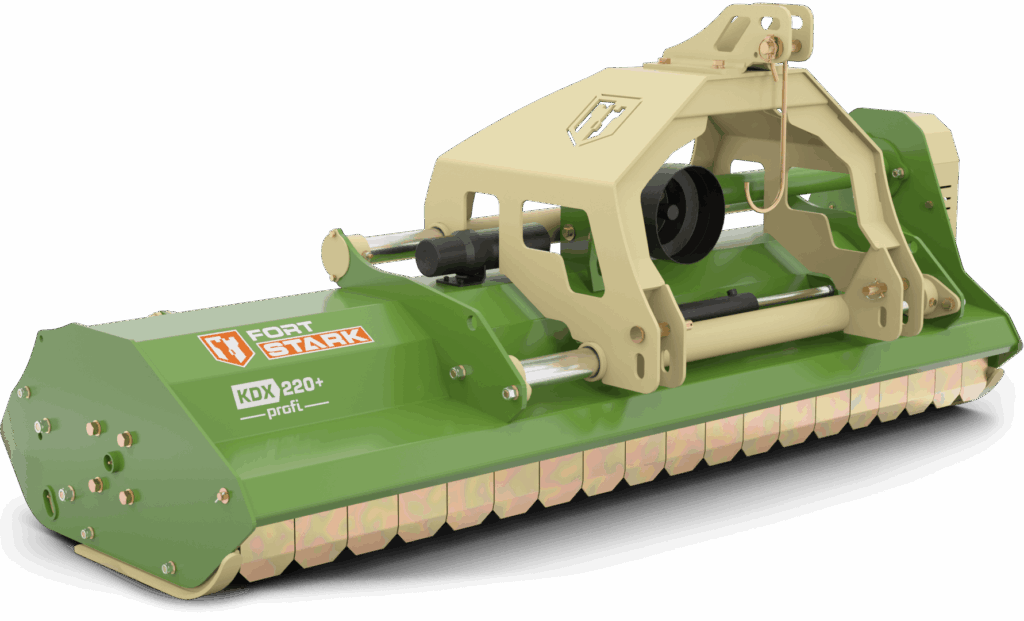

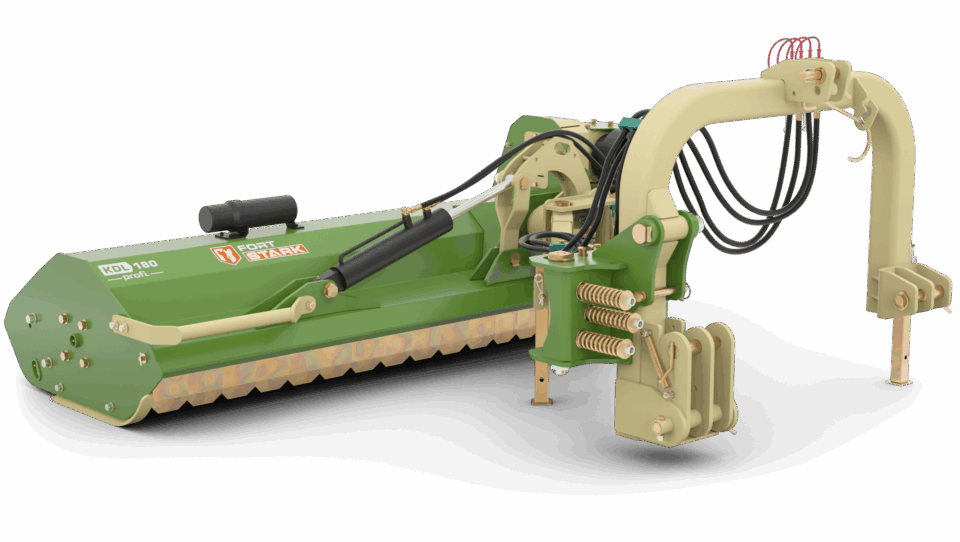

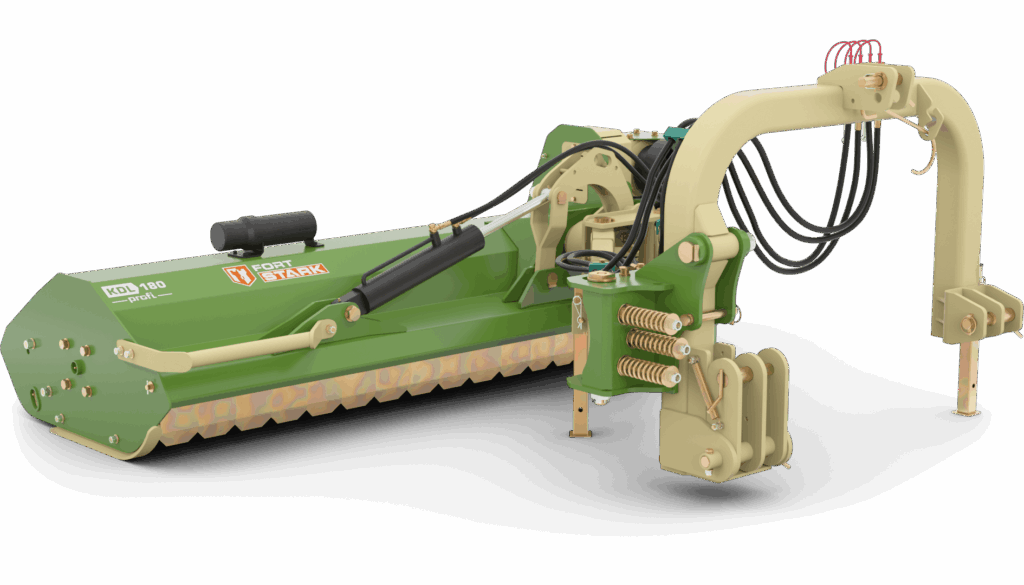

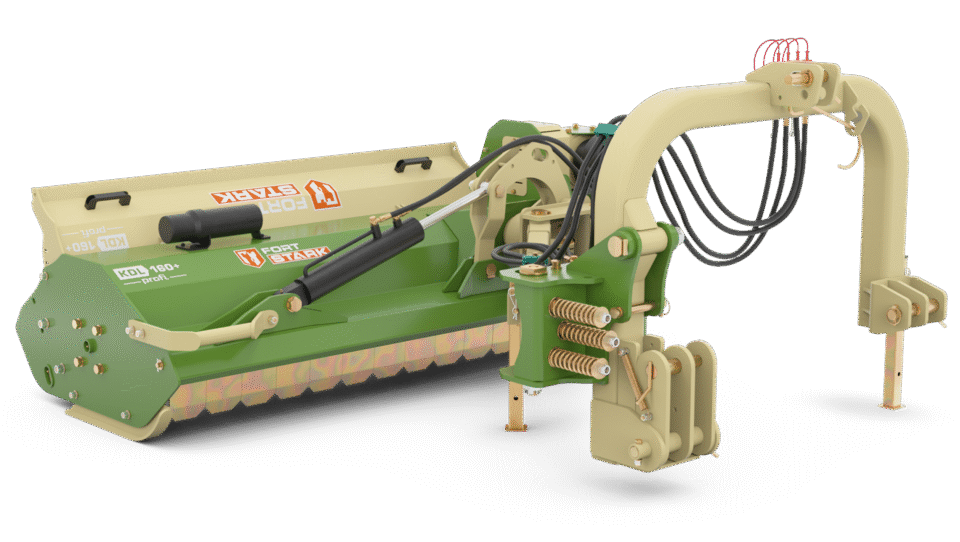

Blade-shift system cutting bar provides a precise mulching result. The smaller the clearance between the cutting bar and the rotor, the greater the suction effect. This means that even old crop residues that have previously been driven over can be processed reliably. The mulching of maize stover, for example, requires different a shredding configuration compared to the chopping of catch crops.

In the event of meeting an obstruction, it protects the structural parts from potential breakages and accidental damage. As the head is forced back by the obstruction, some of the oil contained in the hydraulic cylinder of the machine transfers into the nitrogen pressurized accumalator which brings the machine back to working position once the obstacle has been passed

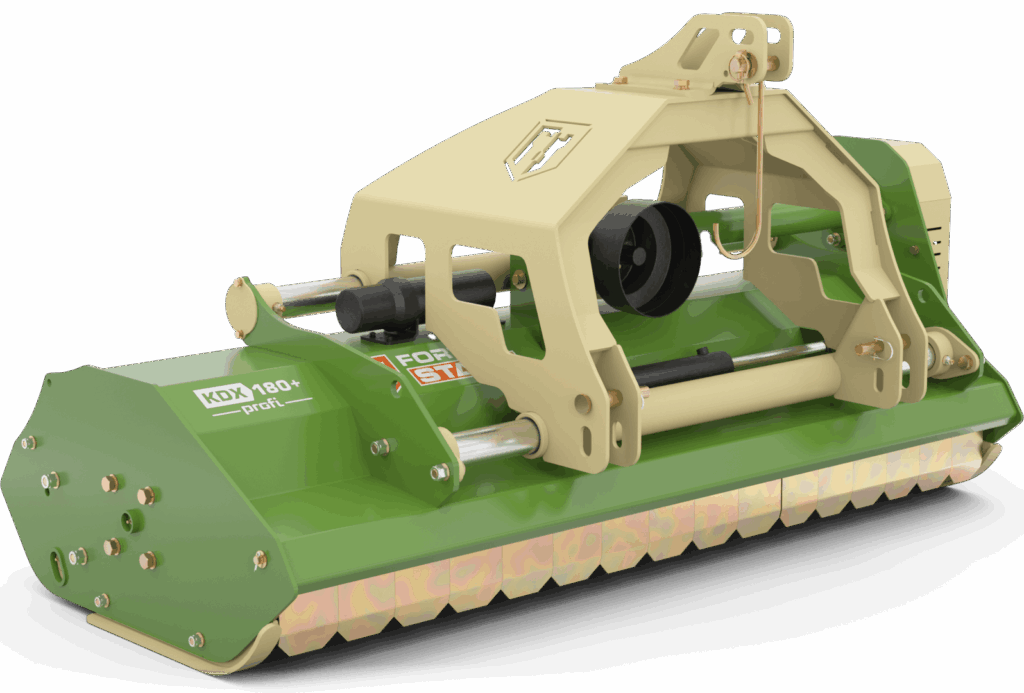

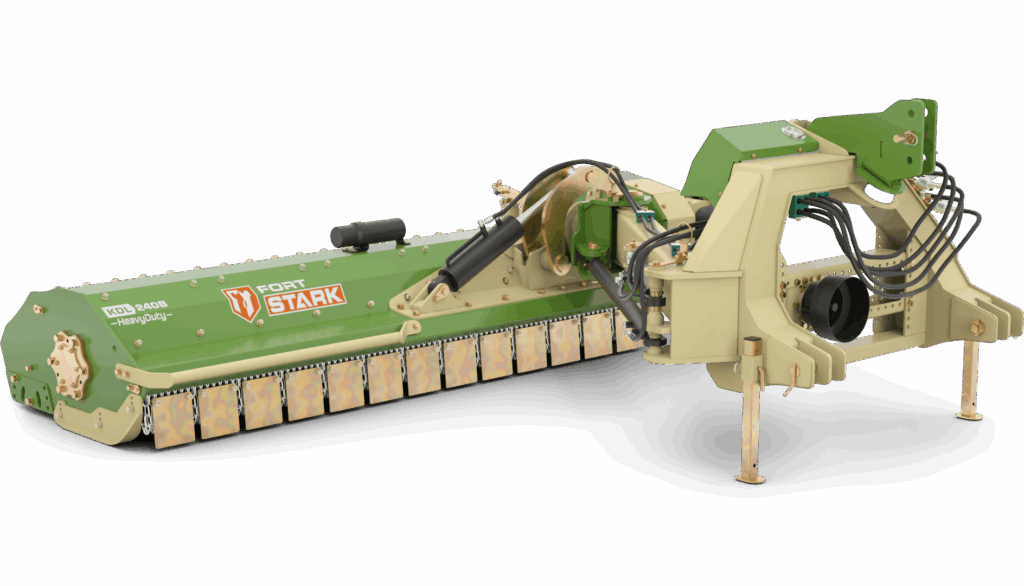

Mulching chamber KDL-B HD designed to allow for an adjustable mulching volume; by changing the position of the flow flap and pivoting rear roller it is possible to obtain two different types of work.

a) Turbo-mulcher grass mowing function: the flow flap remains up, and the mulched product is thrown out of the machine (cutting of grass, thick vegetation … )

b) Wood-mulching function: with the flow flap kept let down the wo-oden residues are finelymulched: they remain within the chamber until they are mulched as finely as possible (vines, underbrush, prunings, wood … )

The cutting chamber on features a double-skinned construction (5 + 4 mm) The toothed counter blades allow the machine to mulch even the more voluminous residues and thicker branches into fine pieces. The body is reinforced with the addition of a sheet metal internal housing for extra strength.

The knives has a self-cleaning and exchangeable design. It ensures uniform shredding of all of the material. Long material is fed through the rotor in a second step in the crop flow, whereas material that is already shredded passes through. The result is a homogeneous mulch.

Optimal power flow due to swing drive system

Automatic belt tensioning keeps the drive belt under tension, whether it is cold or warm and whether the belt is new or already run in. Once adjusted, the tension is automatically maintained at the set level.